Ever dream of cruising effortlessly across the water, your boat engine humming smoothly beneath you? A reliable engine is the heart of any boating adventure, and smart boat owners know that protecting this vital component is paramount. One of the most effective ways to ensure longevity and peak performance is by installing a closed cooling system.

Imagine your boat engine as a finely tuned machine, constantly working to propel you through the waves. Like any hardworking machine, it generates heat, and managing that heat efficiently is crucial. A closed cooling system acts as a protective shield, keeping your engine operating within optimal temperature ranges, even under demanding conditions.

Unlike traditional open cooling systems that draw raw water directly from the surrounding environment, a closed cooling system circulates a coolant mixture through a dedicated loop, much like the system in your car. This ingenious setup isolates the engine from the corrosive effects of saltwater, algae, and debris, significantly reducing wear and tear and extending the lifespan of your engine.

Historically, open cooling systems were the standard, but the development of closed systems marked a significant advancement in marine engine technology. Early versions were primarily used in larger vessels, but as technology progressed and costs decreased, they became increasingly accessible to smaller recreational boats. Today, recognizing the benefits of a closed-loop system, many boat owners are retrofitting their vessels for enhanced engine protection.

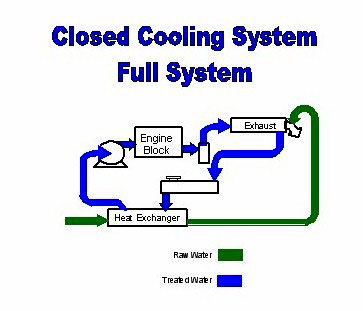

The core principle of a closed cooling system for boats involves circulating a coolant mixture, usually a combination of antifreeze and distilled water, through a closed loop within the engine. This mixture absorbs heat generated by the engine and is then pumped through a heat exchanger, where the heat is transferred to raw water drawn from outside the boat. The cooled coolant then returns to the engine to continue the cycle. This process prevents saltwater and other contaminants from entering the engine block, minimizing corrosion and extending its life.

One of the primary benefits of a closed cooling system is its superior protection against corrosion. By isolating the engine from raw water, the system eliminates the harmful effects of saltwater, preventing rust and other forms of corrosion that can significantly shorten engine life. Secondly, closed systems maintain a consistent engine temperature, leading to improved performance and fuel efficiency. Finally, they reduce the risk of clogging and damage caused by debris and marine growth, simplifying maintenance and saving you time and money.

Implementing a closed cooling system requires careful planning and execution. First, assess your boat's current cooling system and determine the appropriate size and type of closed system for your engine. Consult a qualified marine mechanic for guidance and professional installation. Ensure regular maintenance, including coolant checks and heat exchanger cleaning, to maintain optimal system performance. A successful installation will result in a more reliable, longer-lasting engine, ultimately enhancing your boating experience.

Here's a checklist to guide your closed cooling system project: 1. Consult a marine mechanic. 2. Determine the appropriate system size. 3. Purchase a high-quality system. 4. Schedule professional installation. 5. Establish a regular maintenance routine.

There are several resources available to help you learn more about closed cooling systems. Consult your local marine supply store, search online forums dedicated to boating, and check out manufacturer websites for detailed information and specifications.

Advantages and Disadvantages of Closed Cooling Systems

| Advantages | Disadvantages |

|---|---|

| Extended engine life | Higher initial cost |

| Improved engine performance | More complex installation |

| Reduced maintenance | Requires specialized maintenance |

| Better corrosion protection | Potential for leaks and failures |

Best Practices

1. Use the correct coolant mixture.

2. Regularly inspect the heat exchanger.

3. Check for leaks and address them promptly.

4. Flush the system periodically.

5. Winterize the system properly in cold climates.

Examples of Closed Cooling System Applications

1. Inboard diesel engines in sailboats.

2. High-performance powerboats.

3. Commercial fishing vessels.

4. Luxury yachts.

5. Large outboard motors.

Challenges and Solutions

1. Leak in the heat exchanger: Solution: Repair or replace the heat exchanger.

2. Coolant loss: Solution: Identify and fix the leak, refill the coolant.

3. Overheating: Solution: Check for blockage in the system, inspect the thermostat and water pump.

4. Corrosion within the system: Solution: Flush the system and use the correct coolant mixture.

5. Airlock in the system: Solution: Bleed the system to remove trapped air.

Frequently Asked Questions

1. How often should I change the coolant? (Every two years or according to manufacturer recommendations)

2. What type of coolant should I use? (A marine-specific antifreeze mixed with distilled water)

3. How do I winterize a closed cooling system? (Drain the raw water side and add antifreeze to the closed loop)

4. How can I tell if my heat exchanger is faulty? (Overheating, coolant leaks, reduced engine performance)

5. Can I install a closed cooling system myself? (It's recommended to have a qualified mechanic perform the installation)

6. How much does a closed cooling system cost? (Varies depending on engine size and system complexity)

7. What are the signs of a leak in the system? (Low coolant level, visible drips, or overheating)

8. How do I bleed air from the system? (Consult your engine's manual for specific instructions)

Tips and Tricks

Regularly inspect hoses and clamps for signs of wear and tear. Carry spare coolant and distilled water on board. Learn how to bleed the system yourself to address potential airlocks.

Investing in a closed cooling system for your boat engine is a decision that pays dividends in the long run. By protecting your engine from corrosion, maintaining optimal operating temperatures, and simplifying maintenance, a closed system enhances performance, extends engine life, and reduces overall operating costs. While the initial investment might seem higher compared to an open system, the long-term benefits, including increased resale value, far outweigh the upfront expense. Taking proactive steps to safeguard your boat's engine ensures countless hours of smooth sailing and worry-free adventures on the water. Don't let corrosion and costly repairs sink your boating dreams; make the smart investment in a closed cooling system today and enjoy the peace of mind that comes with knowing your engine is well-protected. Contact a local marine mechanic to discuss your options and embark on a journey of enhanced boating enjoyment.

From starship troopers to halo the enduring allure of sci fi military armor

Deciphering the cover letter font size code a guide to perfect readability

Elizabeth afton fnaf books unlocking the lore

Mercruiser 50 Cooling System Diagram - Khao Tick On

closed cooling system boat - Khao Tick On

closed cooling system boat - Khao Tick On

The Ultimate Guide to Understanding Mercruiser Closed Cooling System - Khao Tick On

What Is A Closed Cooling System On A Boat at David Tai blog - Khao Tick On

closed cooling system boat - Khao Tick On

Closed circuit cooling system Volvo MD2 MD11 Heat exchanger - Khao Tick On

closed cooling system boat - Khao Tick On

Closed Cooling System Boat - Khao Tick On

closed cooling system boat - Khao Tick On

What Is A Closed Cooling System On A Boat at David Tai blog - Khao Tick On

Closed Water Cooling System Now What - Khao Tick On

Marine Closed Cooling Systems - Khao Tick On

The Ultimate Guide to Understanding Mercruiser Closed Cooling System - Khao Tick On

Boat Engine Cooling Diagram - Khao Tick On