Tired of white-knuckle towing experiences with your boat trailer? Is your current braking system feeling less than reliable? Upgrading to disc brakes might be the solution you've been searching for. This comprehensive guide will navigate you through the process of boat trailer disc brake installation, ensuring you achieve optimal braking performance and enhanced safety on the road.

For years, drum brakes were the standard for boat trailers. However, drum brakes are susceptible to various issues, including reduced performance when wet, difficult maintenance due to their enclosed design, and a tendency to overheat during prolonged braking, especially when hauling heavier boats. Disc brakes have become a popular upgrade, offering superior stopping power, improved reliability, and easier maintenance.

The shift towards disc brakes on boat trailers reflects a growing emphasis on safety and improved performance. With the increasing size and weight of boats, the demands on trailer braking systems have intensified. Disc brakes offer a more effective and reliable means of controlling these heavier loads, significantly reducing stopping distances and enhancing overall control.

A key issue when transitioning to disc brakes is ensuring compatibility with your existing trailer axle and hubs. Careful measurement and selection of the correct kit are crucial for a successful installation. Choosing the right components, including calipers, rotors, and hydraulic lines, will also affect the system's longevity and performance.

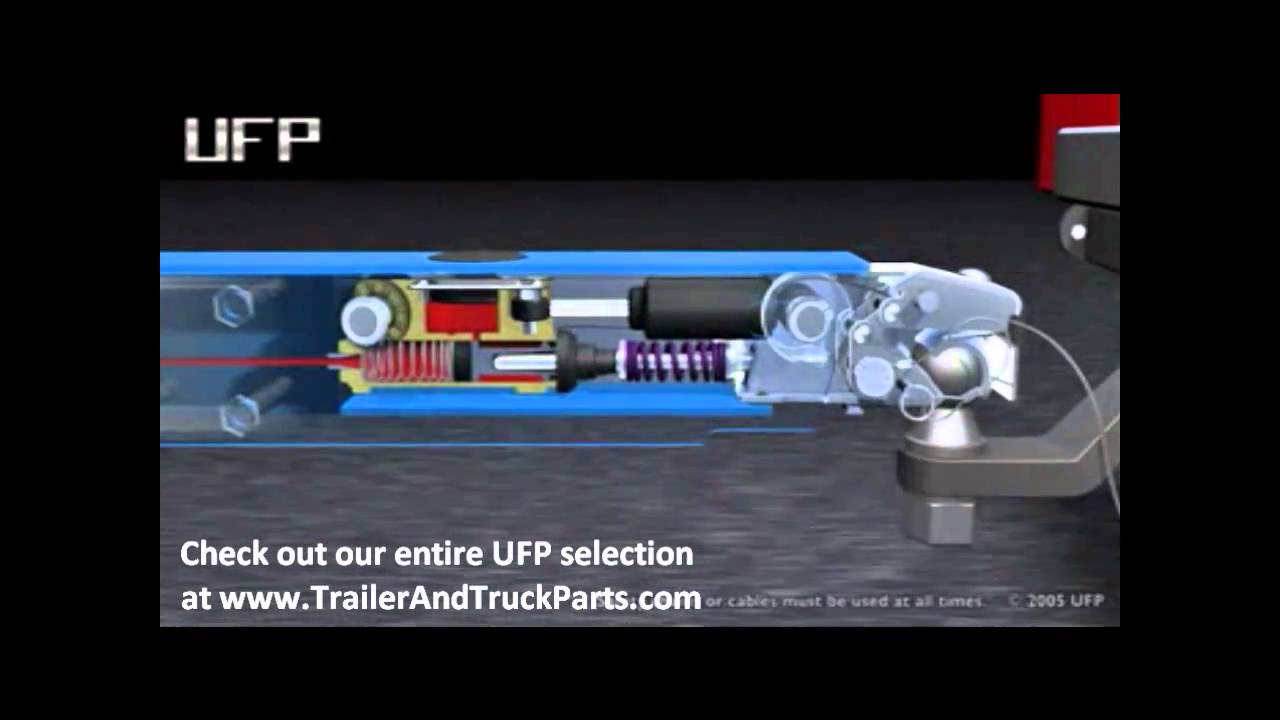

Understanding the basic components of a disc brake system is essential for a smooth installation. The rotor, a metal disc attached to the wheel hub, rotates with the wheel. The caliper houses the brake pads, which clamp onto the rotor when the brakes are applied, creating friction and slowing the wheel. Hydraulic fluid, pressurized by the master cylinder, activates the calipers. Mastering these concepts simplifies the process of disc brake conversion.

One of the main benefits of disc brakes is their superior stopping power, especially in wet conditions. Unlike drum brakes, disc brakes are less affected by water, providing consistent performance regardless of weather. This improved stopping ability significantly enhances safety, allowing for quicker and more controlled stops.

Another advantage of disc brakes lies in their ease of maintenance. Unlike drum brakes, which require disassembly for inspection and adjustment, disc brake components are readily accessible. This simplified maintenance process saves time and effort, allowing for quick inspections and pad replacements.

Furthermore, disc brakes dissipate heat more efficiently than drum brakes, reducing the risk of brake fade during prolonged descents or heavy braking. This improved heat dissipation translates to more consistent performance and reduced wear and tear on the brake components.

Action Plan for Disc Brake Installation: Before you begin, gather the necessary tools and components, including a disc brake conversion kit, jack stands, wrenches, and brake fluid. Carefully follow the instructions provided with your specific kit, ensuring each step is completed accurately.

Step-by-step Guide: 1. Securely lift and support the trailer using jack stands. 2. Remove the wheels and existing drum brake assembly. 3. Install the new disc brake mounting bracket. 4. Attach the caliper and rotor. 5. Connect the hydraulic lines and bleed the brakes.

Checklist: □ Correct disc brake conversion kit. □ Jack stands and wheel chocks. □ Wrenches and sockets. □ Brake fluid. □ Brake bleeding kit. □ Safety glasses and gloves.

Recommendations: Consult your trailer manufacturer's guidelines or refer to reputable online forums and communities dedicated to boat trailers. Several online retailers specialize in trailer parts and offer comprehensive installation guides.

Advantages and Disadvantages of Disc Brakes

| Advantages | Disadvantages |

|---|---|

| Superior Stopping Power | Higher Initial Cost |

| Better Performance in Wet Conditions | More Complex System |

| Easier Maintenance | Potential for Corrosion in Marine Environments |

Best Practices: 1. Choose a high-quality marine-grade disc brake kit. 2. Thoroughly clean and inspect all components before installation. 3. Properly bleed the brakes to ensure optimal performance. 4. Regularly inspect and maintain the system. 5. Use corrosion-resistant lubricants and hardware.

Real Examples: Various boat owners have reported significant improvements in braking performance after converting to disc brakes, particularly when towing heavier boats down steep inclines or in adverse weather conditions.

Challenges and Solutions: One common challenge is compatibility issues between the new disc brake system and the existing axle. Solution: Ensure you select a kit specifically designed for your trailer's axle type.

FAQs: 1. Are disc brakes better than drum brakes for boat trailers? Yes, generally disc brakes offer superior performance and reliability. 2. How much does a disc brake conversion cost? The cost varies depending on the kit and trailer type. 3. Can I install disc brakes myself? Yes, with the right tools and instructions. 4. How often should I maintain my disc brakes? Regular inspections and maintenance are recommended. 5. Do I need special tools to install disc brakes? Basic hand tools and a brake bleeding kit are usually sufficient. 6. What type of brake fluid should I use? Consult your kit instructions for the recommended brake fluid type. 7. How do I bleed the brakes? A brake bleeding kit and a helper can simplify the process. 8. Are there any special considerations for saltwater environments? Using marine-grade components helps prevent corrosion.

Tips and Tricks: Use a torque wrench to ensure proper tightening of all bolts and fasteners. Apply anti-seize compound to threaded connections to prevent corrosion. Carefully inspect the hydraulic lines for any leaks or damage.

In conclusion, upgrading your boat trailer to disc brakes represents a significant investment in safety and performance. The enhanced stopping power, improved reliability, and ease of maintenance make disc brakes a worthwhile upgrade for any boat owner. While the initial cost may be higher than drum brakes, the long-term benefits of increased safety, reduced maintenance headaches, and enhanced control outweigh the initial investment. By following the installation guidelines and best practices outlined in this guide, you can confidently tackle this project and enjoy the peace of mind that comes with a reliable and effective braking system. Don't compromise on safety – upgrade to disc brakes and experience the difference.

Backpacking blues conquering dolor en la parte media de la espalda

Unraveling the mystery of 18 flexible duct at home depot

Depeche mode electrifies san antonio

Boat Trailer Brake Part 10 Hub Disc Rotor L68149 Lm12749 Bearing - Khao Tick On

Gooseneck Trailer With Electric Over Hydraulic Brakes at Damion Mesta blog - Khao Tick On

How to Replace Disc Brake Pads 6 Steps - Khao Tick On

Kodiak Boat Trailer Slip - Khao Tick On

How To Change Brakes On A Boat Trailer at Margaret Schisler blog - Khao Tick On

Electric Trailer Brakes Breakaway Kit - Khao Tick On

can you install electric brakes on a boat trailer - Khao Tick On

Kodiak 8 Lug Dacromet Coated Integral Rotor 916 Stud Diameter - Khao Tick On

3x3 STR w10 Disc Brakes - Khao Tick On

Trailer Brakes Work Then Stop Working at Ashley Jones blog - Khao Tick On

Boat Trailer Brakes Dragging at Kimberly Jones blog - Khao Tick On

6300 Boat Trailer with Disc Brakes - Khao Tick On

Installing Surge Brakes On A Trailer - Khao Tick On

The Lowdown on Trailer Brakes - Khao Tick On

Installing Disc Brakes on Your Trailer - Khao Tick On