Is your boat's bilge pump leaving you high and dry? A malfunctioning bilge pump can be a nightmare, turning a relaxing day on the water into a frantic bailing session. But fear not! This comprehensive guide will demystify the process of wiring a 3-wire bilge pump, giving you the confidence to tackle this essential boat maintenance task.

Connecting a 3-wire bilge pump might seem daunting, but with the right knowledge and a little patience, it's a manageable DIY project. This guide will walk you through each step, providing clear explanations and practical tips to ensure a successful installation. We'll cover everything from identifying the wires to troubleshooting common issues, empowering you to keep your boat afloat and worry-free.

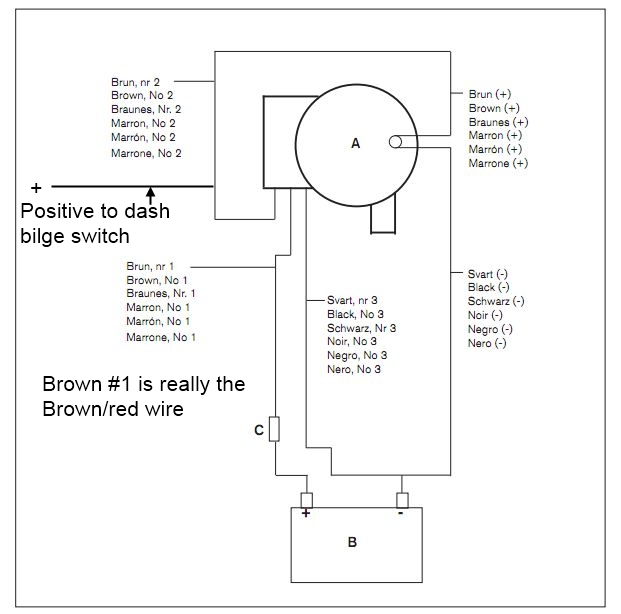

The three wires on a bilge pump represent positive, negative, and the automatic switch. Understanding the role of each wire is crucial for correct wiring. The positive wire provides power to the pump, the negative wire completes the circuit, and the automatic switch wire activates the pump when water reaches a certain level. We'll delve deeper into these connections later, providing clear diagrams and instructions.

Historically, bilge pumps were manually operated, requiring constant monitoring and intervention. The advent of automatic bilge pumps with float switches revolutionized boat safety, providing a reliable system for removing unwanted water. The 3-wire setup allows for this automatic function, offering peace of mind while you're on the water.

Incorrect wiring can lead to several issues, including a non-functional pump, a constantly running pump, or even electrical hazards. This guide will help you avoid these pitfalls by providing clear, step-by-step instructions and helpful tips for troubleshooting.

The three wires typically have different colors. Brown is often used for positive, black for negative, and blue for the automatic switch. However, always consult your pump's wiring diagram to confirm the wire functions.

Benefits of a properly wired 3-wire bilge pump include automatic water removal, increased boat safety, and reduced risk of flooding. An automatic bilge pump ensures water is removed even when you're not onboard, preventing potential damage. This automatic function significantly enhances boat safety by preventing sinking due to accumulated water. By automatically removing water, a properly wired bilge pump reduces the risk of flooding, protecting your boat and its contents.

Action Plan:

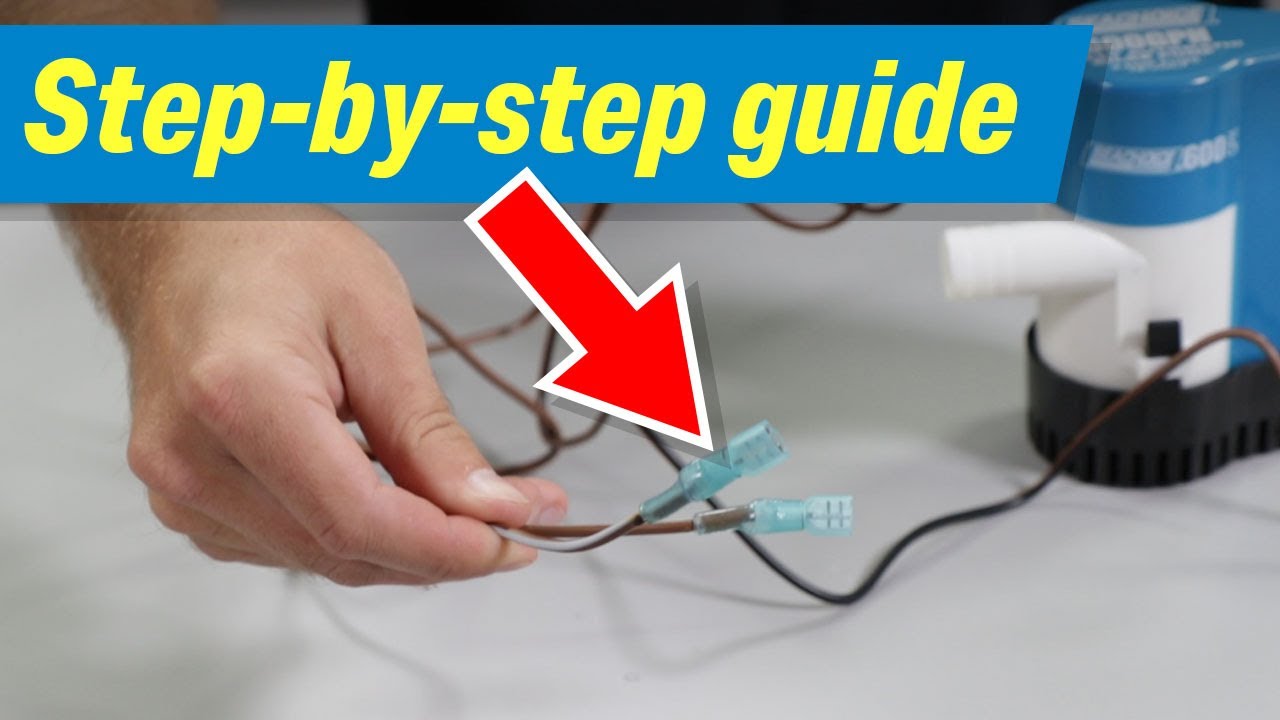

1. Gather your materials: wire strippers, crimp connectors, marine-grade wire, fuse, and a switch (if not using the automatic float switch).

2. Disconnect the battery.

3. Identify the wires on your bilge pump.

4. Connect the positive wire through a fuse to the positive terminal of the battery or a switched power source.

5. Connect the negative wire to the negative terminal of the battery.

6. Connect the automatic switch wire to the float switch.

7. Test the system.Advantages and Disadvantages of 3-Wire Bilge Pumps

| Advantages | Disadvantages |

|---|---|

| Automatic operation | Requires a properly functioning float switch |

| Increased safety | Can be more complex to wire than a 2-wire pump |

| Reduced risk of flooding | Susceptible to float switch malfunctions |

Best Practices:

1. Use marine-grade wire for corrosion resistance.

2. Install an inline fuse to protect the circuit.

3. Ensure all connections are waterproof.

4. Test the system regularly.

5. Consult your bilge pump's wiring diagram.FAQ: 1. What if my pump doesn't turn on? Check the fuse, connections, and float switch. 2. Can I wire a 3-wire pump to a 2-wire system? Yes, but you'll lose the automatic functionality. 3. What size fuse should I use? Consult your pump's specifications. 4. Where should I mount the float switch? In the lowest part of the bilge. 5. What if my float switch is faulty? Replace it with a new one. 6. Can I use automotive wire? It's not recommended. Use marine-grade wire. 7. How often should I test my bilge pump? At least once a month. 8. What if my pump runs constantly? Check the float switch for sticking or debris.

Tips & Tricks: Use dielectric grease on all connections to prevent corrosion. Double-check all your connections before reconnecting the battery. Consider adding a manual override switch for added control.

In conclusion, wiring a 3-wire bilge pump is a crucial skill for any boat owner. This guide has provided you with the knowledge and steps to confidently tackle this task, ensuring the safety and longevity of your vessel. By understanding the function of each wire, following the correct procedures, and implementing best practices, you can effectively protect your boat from flooding and enjoy peace of mind on the water. A functioning bilge pump is an essential safety feature, and taking the time to wire it correctly is a small investment that can prevent major headaches down the line. Don't wait until you're facing a flooded bilge - take the initiative and master the art of 3-wire bilge pump wiring today!

Bts logo purple png a symbol of fandom and identity

Conquer the long bathroom layout ideas to maximize your space

Unraveling the allure of amazon owl stuffed toys

Bilge Pump Float Switch Wiring Diagram - Khao Tick On

How To Wire An Automatic Bilge Pump - Khao Tick On

Attwood Float Switch Wiring Diagram - Khao Tick On

Bilge Pump Float Switch Wiring - Khao Tick On

How to wire a bilge pump - Khao Tick On

Rule Float Switch Wiring - Khao Tick On

3 Wire Bilge Pump Wiring Diagram - Khao Tick On

wire a bilge pump switch - Khao Tick On

How To Wire A Float Switch For A Bilge Pump at James Belcher blog - Khao Tick On

Rule Bilge Pump Wiring Instructions - Khao Tick On

How To Wire A Rule Bilge Pump - Khao Tick On

How To Wire A Bilge Pump Switch - Khao Tick On

Wiring Diagram For An Automatic Bilge Pump Wiring Bilge Pump Diagram - Khao Tick On

wire a bilge pump switch - Khao Tick On

how to wire a bilge pump with 3 wires - Khao Tick On