Is your boat's safety and your peace of mind worth a few carefully connected wires? A properly wired bilge pump is the silent guardian against unexpected leaks and flooding, safeguarding your vessel and preventing potential disaster. This comprehensive guide dives deep into the world of bilge pump wiring, equipping you with the knowledge and confidence to tackle this critical boat maintenance task.

A bilge pump is the heart of your boat's defense against unwanted water. It works tirelessly in the background, removing accumulated water from the bilge—the lowest part of your boat's hull. But a pump without power is useless. Understanding bilge pump wiring diagrams and best practices is crucial for ensuring your pump operates reliably when you need it most.

The concept of removing unwanted water from boats dates back centuries. Early methods involved manual bailing, a laborious and often ineffective process. The advent of mechanical pumps, followed by electrical bilge pumps, revolutionized boat safety. Today, reliable automatic bilge pumps are considered essential equipment for any boat, from small fishing boats to large yachts. The importance of correct bilge pump installation cannot be overstated: a faulty connection can render the pump inoperative, leaving your boat vulnerable to flooding.

One of the main issues related to bilge pump electrical hookup is improper wiring, leading to malfunctions or even complete failure. Common problems include loose connections, corroded wires, and blown fuses. Another challenge is choosing the right type of wire and fuse for the specific pump and boat. Using incorrect components can create safety hazards and damage the pump. Understanding the fundamentals of electrical circuits and following manufacturer guidelines are essential for a successful installation.

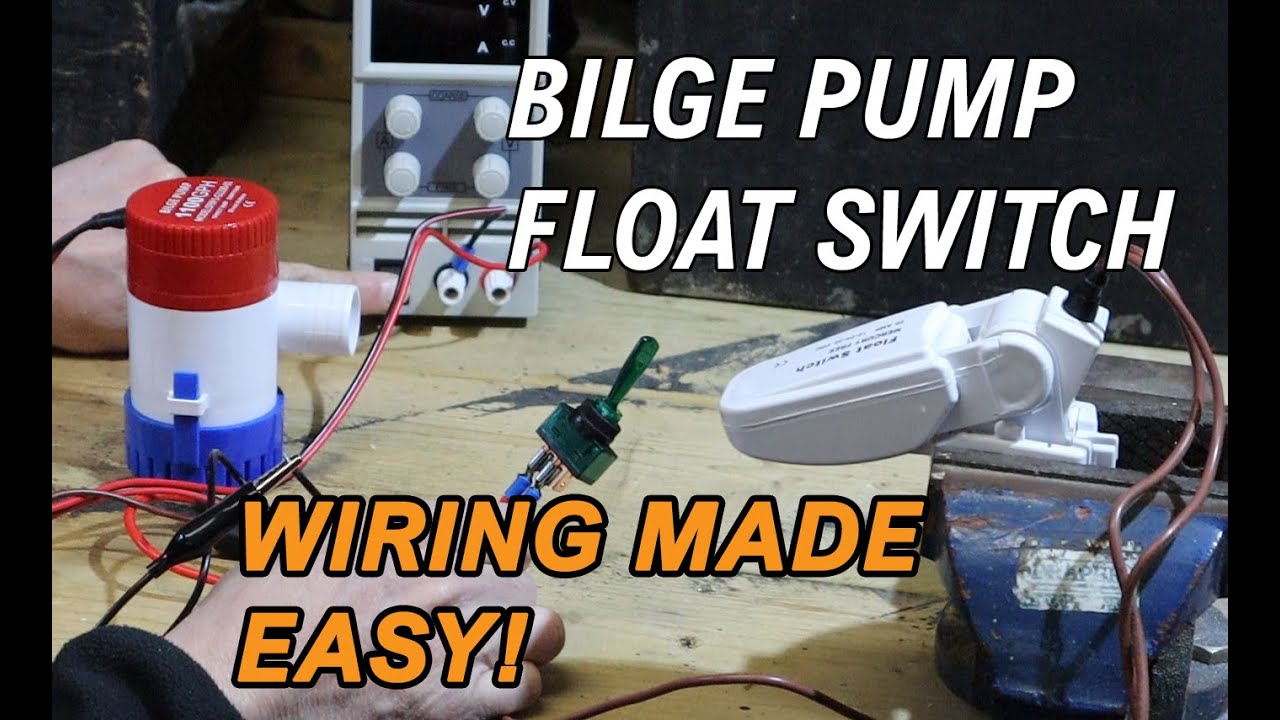

Bilge pump wiring involves connecting the pump's power wires to the boat's electrical system, typically through a fuse and a switch. The switch allows you to manually activate the pump or set it to automatic mode, where a float switch activates the pump when the water level in the bilge reaches a certain point. A simple bilge pump wiring setup involves connecting the positive wire from the pump to the positive terminal of the battery (via a fuse) and the negative wire to the negative terminal. The switch is placed in line with the positive wire to control the flow of electricity.

Three key benefits of correctly configuring a bilge pump system include: increased boat safety (preventing sinking), reduced maintenance (automated water removal), and peace of mind knowing your vessel is protected even when unattended. Imagine being caught in a storm and discovering your manually operated pump has failed. A correctly wired automatic bilge pump could save your boat in such a situation.

Creating a successful bilge pump connection starts with planning. Refer to your pump's wiring diagram and choose appropriate marine-grade wiring and fuses. Next, ensure all connections are secure and waterproof. Finally, test the system thoroughly to confirm it operates as expected in both manual and automatic modes.

A basic checklist for bilge pump setup includes: Marine-grade wiring, appropriately sized fuse, float switch (for automatic operation), waterproof connectors, and a properly sized pump for your boat.

A step-by-step guide includes: disconnect the battery, connect the float switch, connect the pump to the switch, connect the wiring to the fuse panel or battery (with an inline fuse), test the connections, reconnect the battery, and test the pump's operation.

Advantages and Disadvantages of Proper Bilge Pump Wiring

| Advantages | Disadvantages |

|---|---|

| Increased Safety | Initial Cost of Components |

| Automated Water Removal | Potential for Wiring Errors |

| Peace of Mind | Time Investment for Installation |

Five best practices: Use marine-grade wiring, install an inline fuse, use waterproof connectors, secure all wiring to prevent chafing, and test the system regularly.

Five real-world examples: A sailboat relying on its bilge pump during a storm, a fishing boat dealing with spray and rain, a pontoon boat encountering waves, a kayak with a small bilge pump for unexpected leaks, and a large yacht with multiple pumps for redundancy. Details would involve the specific pump types and wiring setups used in each scenario.

Five challenges: Corrosion, loose connections, blown fuses, incorrect wiring, and pump failure. Solutions include: using corrosion-resistant materials, ensuring tight connections, using the correct fuse size, following wiring diagrams, and regular pump maintenance.

FAQs: What size wire should I use? How do I choose the right fuse? What is a float switch? How do I test my bilge pump? Where should I mount the pump? How often should I check my bilge pump? What kind of maintenance does a bilge pump require? Why is my bilge pump not working?

Tips and tricks: Use dielectric grease on connections, label wires clearly, double-check all connections, and consult a professional if you are unsure about any aspect of the installation.

Proper bilge pump wiring is not just a task; it's an investment in the safety and longevity of your boat. From understanding the historical context of water removal in vessels to mastering the intricacies of modern electrical systems, this guide has equipped you with the knowledge to confidently tackle this essential project. Remember, a functioning bilge pump is much more than a piece of equipment; it's a critical safety system that can protect your vessel, your passengers, and your investment. By following best practices, performing regular maintenance, and addressing potential issues proactively, you can ensure your bilge pump is always ready to perform its vital duty. Don't wait for disaster to strike—take action today and safeguard your boat against the unexpected. Invest the time to learn, understand, and implement proper bilge pump wiring. Your peace of mind on the water is worth it.

Navigating medicare supplement plans in north carolina

Honoring memory crafting thoughtful invitations for a memorial mass

Unlocking unique style exploring collins fresh and original decor

Wiring Diagram For Bilge Pump - Khao Tick On

Bilge Pump Wiring Diagram With Float Switch - Khao Tick On

Seachoice Bilge Pump Wiring Diagram - Khao Tick On

Bilge Pump Float Switch Wiring - Khao Tick On

Installing Float Switch To Bilge Pump Page 1 - Khao Tick On

Bilge Pump Float Switch Wiring Diagram - Khao Tick On

DIAGRAM Wiring A Bilge Pump And Float Switch Diagram - Khao Tick On

Boat Bilge Pump Wiring Diagram - Khao Tick On

Bilge Pump Wiring With Float Switch - Khao Tick On

Bilge Pump Float Switch Wiring - Khao Tick On

Mercruiser Bilge Pump Wiring - Khao Tick On

wiring a bilge pump - Khao Tick On

Wiring A Automatic Bilge Pump - Khao Tick On

How To Install A Bilge Pump And Float Switch at Josephine Neal blog - Khao Tick On

Rule Bilge Pump Wireing - Khao Tick On