Ever found yourself staring blankly at a wrench set, wondering what that 3/8" actually means in the metric system you're used to? You're not alone. The clash between the imperial SAE (Society of Automotive Engineers) system and the globally dominant metric system is a constant source of confusion, particularly for those working with tools, machinery, or engineering projects. This guide dives deep into the world of SAE to metric conversion, providing you with the knowledge and resources to navigate this often-perplexing landscape.

The SAE system, born from the inch-pound units commonly used in the United States, often feels like a relic of a bygone era. However, its persistent use in certain industries, particularly automotive and aerospace in the US, necessitates a clear understanding of how to translate these measurements into the more universally accepted metric system. This isn't just about knowing the equivalent of a 1/4" bolt; it's about understanding the nuances of converting different units, from length and weight to volume and pressure.

Converting SAE sizes to their metric counterparts isn't simply a mathematical exercise; it's a crucial skill for ensuring accuracy and avoiding potentially costly mistakes. Imagine machining a part with slightly off measurements due to a conversion error – the consequences could range from minor inconveniences to catastrophic failures. This is especially true in industries with tight tolerances, where even a fraction of a millimeter can make all the difference.

The historical roots of the SAE system are intertwined with the industrial revolution and the unique development of manufacturing in the United States. While the metric system, with its decimal-based simplicity, gained widespread adoption globally, the US largely stuck with the SAE system. This divergence has created a persistent need for conversion, especially as global trade and collaboration increased. This historical context helps us understand why converting between these two systems is such a common requirement today.

Understanding the importance of accurate SAE to metric conversion is paramount for anyone working in a field where these two systems intersect. Whether you're a professional engineer, a DIY enthusiast, or simply someone trying to assemble furniture with instructions in different units, mastering this conversion process is a valuable skill. It's about more than just getting the numbers right; it's about ensuring compatibility, safety, and efficiency in your work.

Converting length involves multiplying the inch value by 25.4 to get millimeters. For example, a 1-inch bolt is equivalent to a 25.4mm bolt. Weight conversion, on the other hand, requires understanding that 1 pound is approximately 0.45 kilograms.

One benefit of using metric equivalents is improved communication with international colleagues and suppliers. Another is reducing the risk of errors in manufacturing and assembly. Finally, adopting metric can simplify design and engineering processes.

A practical action plan for adopting metric involves first identifying the key SAE measurements used in your work. Next, create a conversion chart for easy reference. Finally, gradually integrate metric measurements into your workflow.

Advantages and Disadvantages of SAE to Metric Conversion

| Advantages | Disadvantages |

|---|---|

| Improved international communication | Initial learning curve |

| Reduced errors | Cost of tooling changes (in some cases) |

| Simplified design | Resistance to change in some industries |

One best practice is to always double-check your conversions. Another is to use a reliable conversion tool or chart. Use consistent units throughout a project. Clearly label converted measurements to avoid confusion. Train team members on conversion best practices.

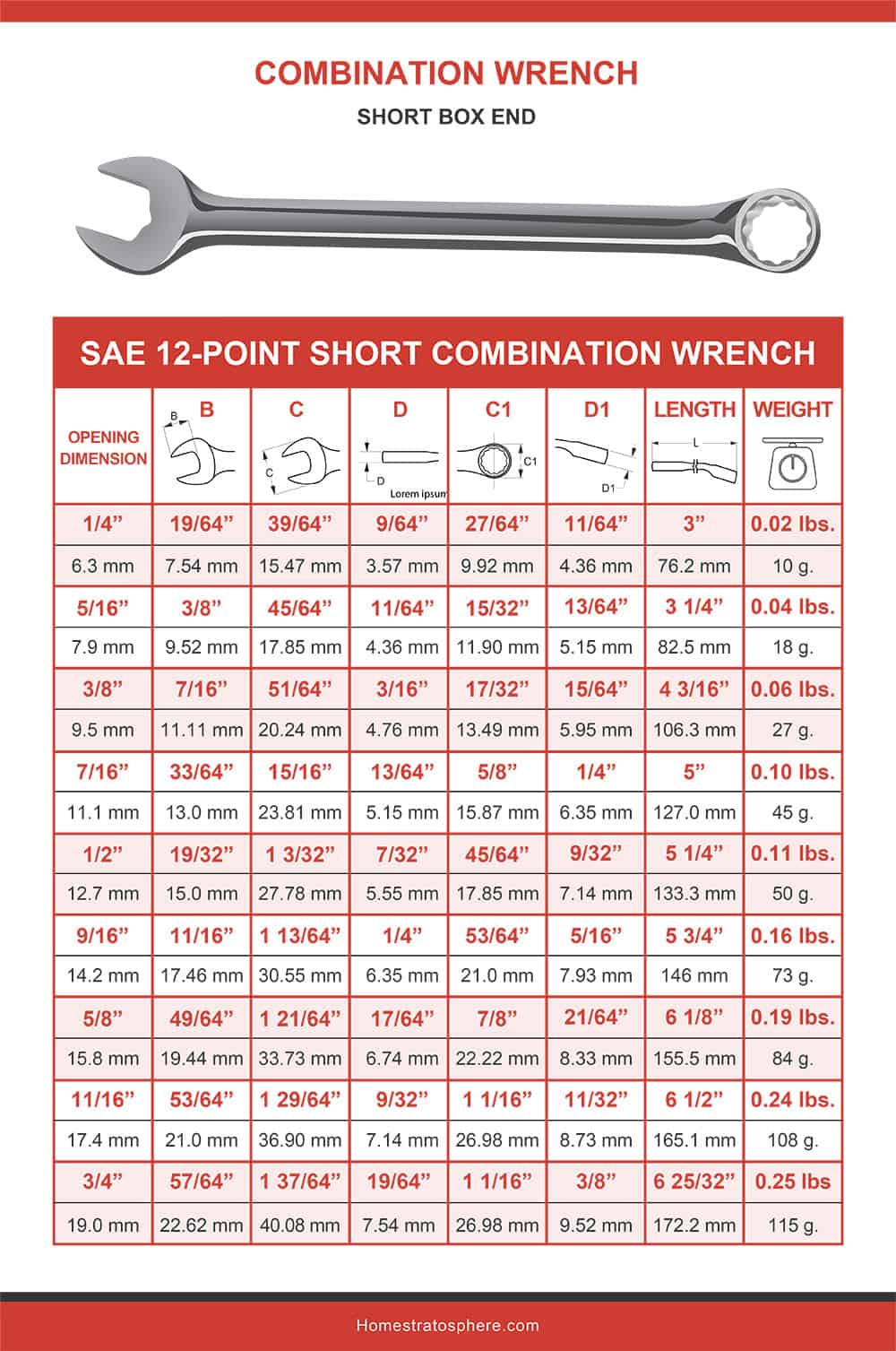

Example 1: Converting wrench sizes for automotive repair. Example 2: Converting pipe diameters for plumbing projects. Example 3: Converting fastener sizes for furniture assembly. Example 4: Converting engine displacement from cubic inches to liters. Example 5: Converting tire pressure from PSI to kPa.

Challenge 1: Resistance to change. Solution: Education and training. Challenge 2: Cost of new tools. Solution: Gradual implementation. Challenge 3: Confusion during the transition. Solution: Clear labeling and communication. Challenge 4: Inconsistent application of metric. Solution: Develop company-wide standards. Challenge 5: Lack of readily available metric parts. Solution: Source from metric suppliers.

FAQ 1: Why is metric used more globally? Answer: Its decimal-based system is simpler. FAQ 2: Is SAE still used? Answer: Yes, predominantly in the US. FAQ 3: What are the most common SAE to Metric conversions? Answer: Length, weight, and volume. FAQ 4: How accurate do conversions need to be? Answer: Depends on the application, but high accuracy is usually essential. FAQ 5: What are some common conversion mistakes? Answer: Not considering significant figures, using the wrong conversion factor. FAQ 6: Where can I find reliable conversion charts? Answer: NIST and other reputable engineering resources. FAQ 7: Are there any online conversion tools? Answer: Yes, numerous online calculators are available. FAQ 8: Is it necessary to memorize all conversion factors? Answer: No, using reliable resources is sufficient.

A useful tip is to label all converted measurements clearly to avoid confusion. Another trick is to create custom conversion charts for the specific units you use most frequently.

In conclusion, converting SAE sizes to metric is a crucial skill in today's interconnected world. Understanding the history, importance, and practical application of this conversion process empowers you to work more effectively, communicate more clearly, and avoid costly errors. From engineering projects to everyday tasks, mastering SAE to metric conversion offers a range of benefits, from improved accuracy and efficiency to enhanced international collaboration. While the transition may present some initial challenges, utilizing the resources, best practices, and tips outlined in this guide will ensure a smooth and successful conversion experience. Embracing the metric system opens doors to a world of standardization and simplifies communication across borders, ultimately leading to greater precision and efficiency in various fields. Take the time to familiarize yourself with the conversion process, practice regularly, and leverage the available tools to make SAE to metric conversion a seamless part of your workflow.

Embracing the silver a guide to gray hair color

Planet protectors engaging kids in the fight against pollution through video

Unleash your creativity the ultimate guide to sci fi character makers

Socket Sizes Standard Chart - Khao Tick On

SAE TO METRIC WRENCH INTERCHANGE - Khao Tick On

Grade 8 Fine Thread Bolt Torque Chart - Khao Tick On

Conversion Chart Metric To Sae - Khao Tick On

Printable Socket Size Chart Metric And Standard - Khao Tick On

Wrench And Socket Size Chart - Khao Tick On

Socket Wrench Sizes Mm - Khao Tick On

Wrench And Socket Size Chart - Khao Tick On

Sae to Metric Conversion Chart in PDF - Khao Tick On

What Are The Most Common Lug Nut Socket Sizes at Yael Wallace blog - Khao Tick On

Wrench Conversion Chart For SAE Metric Sizes W Bolt Diameter Guide - Khao Tick On

Standard Socket Size Chart at Juanita Peters blog - Khao Tick On

Sae Wrench Size Chart - Khao Tick On

List Of Standard And Metric Wrenches at Donna Lally blog - Khao Tick On

Printable Socket Size Chart - Khao Tick On