Ever found yourself staring at your Honda’s wheel assembly, wondering about the seemingly insignificant components that hold everything together? One such crucial element, often overlooked, is the axle nut. It’s the unsung hero ensuring your wheels stay securely attached. This deep dive explores the world of Honda axle nut sizes, their importance, potential problems, and best practices for maintenance.

Getting the correct Honda axle nut size is paramount for safety and proper vehicle function. An incorrect size can lead to a loose wheel, potentially resulting in a dangerous driving situation. Knowing your specific Honda model's requirements is essential, as sizes can vary depending on the year and model.

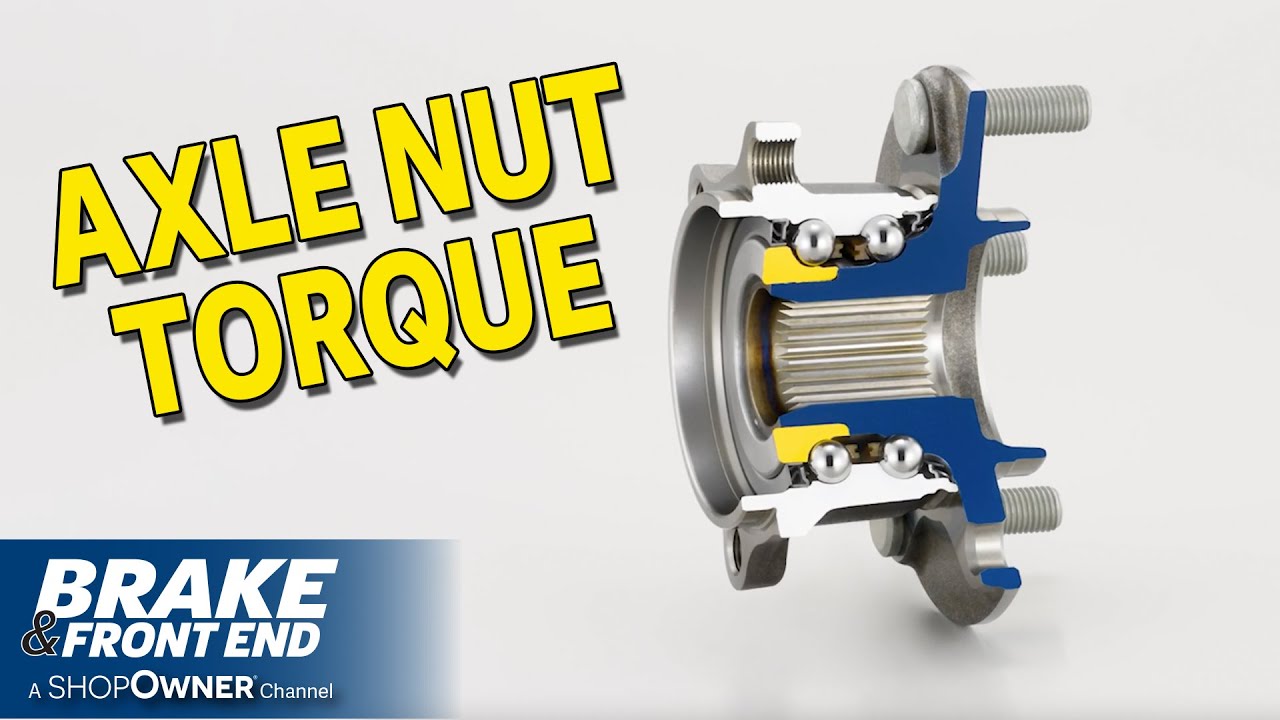

While seemingly simple, the history of the axle nut parallels the evolution of the automobile. Early axle nuts were simpler fasteners, evolving over time into the precisely engineered components we see today. Their role remains critical: securing the wheel hub and bearing assembly to the axle shaft. This allows for smooth rotation while maintaining structural integrity.

The importance of the correct Honda axle nut size cannot be overstated. It’s the linchpin that ensures your wheels remain securely fastened, preventing catastrophic failure. A loose or improperly sized nut can compromise handling, create vibrations, and even lead to complete wheel detachment. Imagine the consequences of a wheel coming off while driving!

Common issues related to Honda axle nuts include stripping, loosening, and corrosion. Stripped threads can result from using the wrong tools or excessive torque. Loosening can occur over time due to vibrations and road conditions. Corrosion can weaken the nut and make it difficult to remove or tighten properly.

The Honda axle nut size is usually specified in millimeters. For example, a common size is 32mm. You'll need a socket wrench of the corresponding size to work with the nut. Always refer to your vehicle's service manual for the precise size and torque specifications.

Benefits of properly installed Honda axle nuts include enhanced safety, improved handling and stability, and prolonged bearing life. A secure wheel connection minimizes the risk of accidents, while proper torque prevents premature wear and tear on wheel bearings.

When working with Honda axle nuts, always consult your vehicle's service manual for the correct size and torque specifications. Use a torque wrench to ensure proper tightening, preventing damage to the nut and surrounding components. Regularly inspect your axle nuts for signs of wear, corrosion, or loosening.

Advantages and Disadvantages of Using Aftermarket Axle Nuts

While genuine Honda axle nuts are recommended, aftermarket options are available. However, choosing wisely is crucial.

| Advantages | Disadvantages |

|---|---|

| Potentially lower cost | Potential quality inconsistencies |

| Wider availability | May not meet Honda's specifications |

Best practices for working with Honda axle nuts include using a quality torque wrench, applying anti-seize lubricant to prevent corrosion, and inspecting the nuts regularly for signs of damage. Always refer to the service manual for the correct torque specifications. Avoid using impact wrenches, as they can easily overtighten the nut.

Real-world examples of Honda axle nut issues include cases of stripped threads due to incorrect tool usage, loose wheels caused by improper tightening, and corrosion leading to difficulty in removal. Addressing these issues promptly is essential for safe and reliable driving.

Challenges related to Honda axle nuts include identifying the correct size, accessing the nut due to surrounding components, and removing corroded nuts. Solutions include consulting the service manual, using specialized tools, and applying penetrating oil to loosen corroded fasteners.

FAQs about Honda axle nuts often include questions about size, torque specifications, and replacement procedures. Consulting your vehicle’s service manual is the best way to get accurate information specific to your model.

Tips and tricks for working with Honda axle nuts include using a six-point socket for a more secure grip, cleaning the threads before installation, and using a breaker bar for stubborn nuts. Always prioritize safety and follow proper procedures.

In conclusion, the humble Honda axle nut plays a vital role in vehicle safety and performance. Understanding its importance, knowing the correct size for your model, and following proper maintenance practices can prevent serious problems and ensure a smooth, safe driving experience. From preventing wheel detachment to minimizing wear and tear on related components, the correct axle nut size and proper installation are crucial. Regular inspections and timely replacements are essential parts of responsible car ownership, contributing significantly to your safety and the longevity of your vehicle. By understanding the information presented in this article, you can take proactive steps to maintain your Honda’s wheel assembly and enjoy peace of mind on the road. Take the time to familiarize yourself with your specific Honda's requirements and invest in the right tools and knowledge. Your safety and the performance of your vehicle depend on it.

Legendary voices celebrating older female singers still gracing the stage

The power and legacy of black women in track and field

Unveiling the book of shadows a personal journey

honda axle nut size - Khao Tick On

Honda Accord Axle Nut Size - Khao Tick On

Honda Accord Lug Nut Torque Spec - Khao Tick On

Toyota Lug Nut Torque Specifications - Khao Tick On

1992 Honda Accord Axle Nut Size - Khao Tick On

2000 Honda Accord Axle Nut Size - Khao Tick On

Honda Accord Axle Nut Torque - Khao Tick On

Honda Accord Axle Nut Size - Khao Tick On

Bmw X3 Rear Axle Nut Torque - Khao Tick On

Honda Fit Lug Nut Torque - Khao Tick On

Ram 1500 Axle Nut Size - Khao Tick On

Honda Accord Axle Nut Size - Khao Tick On