Keeping your boat afloat and free from unwanted water is paramount, and a reliable bilge pump system is essential for achieving this. Johnson bilge pumps are a popular choice among boat owners, known for their durability and performance. But proper Johnson bilge pump installation is crucial for maximizing its effectiveness and ensuring the longevity of your boat. This guide will walk you through everything you need to know about fitting a Johnson bilge pump, from choosing the right model to troubleshooting potential problems.

Before diving into the intricacies of Johnson bilge pump fitting, let's understand why a bilge pump is so important. Water can accumulate in the bilge of your boat from various sources – rain, waves, leaks, or even condensation. A bilge pump automatically removes this water, preventing it from accumulating and potentially causing your boat to sink. A properly installed Johnson bilge pump offers peace of mind, knowing you have a reliable system working to keep your vessel safe.

While the specifics of bilge pump technology have evolved, the fundamental principle has remained the same for decades. Early bilge pumps were often manually operated, requiring constant attention. The introduction of automatic electric bilge pumps, like those manufactured by Johnson, revolutionized boat safety. Johnson has a long history of producing high-quality marine equipment, and their bilge pumps are no exception. They are designed to withstand the harsh marine environment and provide reliable performance, making them a trusted choice for boaters worldwide.

One of the most common issues related to Johnson bilge pump setups involves incorrect wiring. A poorly wired pump may not activate when needed, rendering it useless. Another frequent problem is improper placement of the pump, which can hinder its ability to effectively remove water from the bilge. Choosing the right size pump for your boat is also critical. An undersized pump will struggle to keep up with water ingress, while an oversized pump can quickly drain your battery.

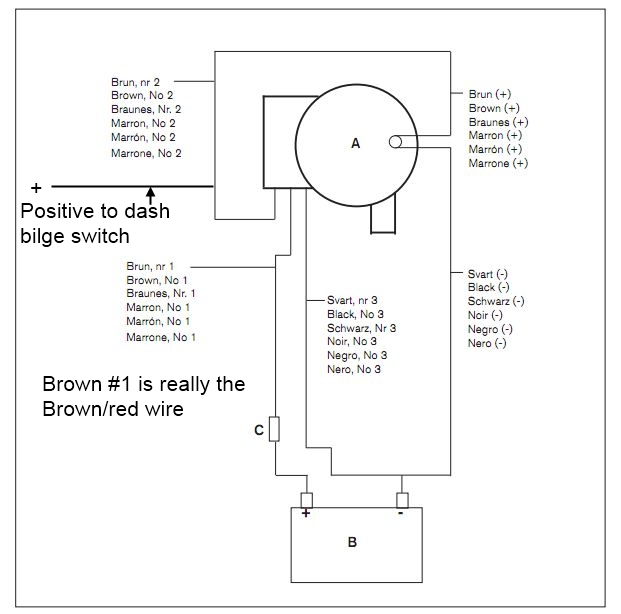

Understanding the components of a typical Johnson bilge pump system is crucial for successful installation. The pump itself is the heart of the system, drawing water from the bilge and expelling it overboard. The float switch is a critical component that automatically activates the pump when the water level reaches a certain point. The wiring connects the pump to the boat's electrical system, providing the power needed for operation. Finally, the discharge hose carries the water from the pump to the outside of the boat.

Three key benefits of correctly installing a Johnson bilge pump include: increased boat safety, reduced risk of damage due to water accumulation, and peace of mind while on the water.

A step-by-step guide for Johnson bilge pump installation would include selecting the correct location, mounting the pump, connecting the wiring, installing the float switch, and testing the system.

Advantages and Disadvantages of Johnson Bilge Pumps

| Advantages | Disadvantages |

|---|---|

| Durable construction | Can be noisy |

| Reliable performance | Initial cost can be higher than some competitors |

Five best practices for Johnson bilge pump installation: 1. Ensure proper wiring, 2. Choose the correct location, 3. Use marine-grade sealant, 4. Test the system regularly, 5. Install a check valve to prevent backflow.

Frequently Asked Questions: 1. How do I choose the right size Johnson bilge pump? 2. What type of wiring should I use? 3. Where should I install the float switch? 4. How often should I test my bilge pump? 5. What maintenance is required for a Johnson bilge pump? 6. How do I troubleshoot common bilge pump problems? 7. What is the warranty on a Johnson bilge pump? 8. Where can I purchase a Johnson bilge pump?

Tips and tricks: Use marine-grade wire and connectors to prevent corrosion. Regularly inspect the float switch for debris. Consider installing a high-water alarm for added safety.

In conclusion, a properly functioning bilge pump is an essential piece of safety equipment for any boat. Johnson bilge pumps offer a reliable solution for keeping your vessel free from unwanted water. By following the guidelines outlined in this comprehensive guide, you can ensure a successful Johnson bilge pump installation, increasing your boat's safety and providing you with peace of mind on the water. Taking the time to understand the nuances of installation and regular maintenance can prevent costly repairs and ensure the long-term performance of your bilge pump system. Remember to consult the manufacturer's instructions for specific details related to your chosen model and always prioritize safety when working with electrical systems on your boat. Investing in a quality bilge pump and installing it correctly is an investment in the safety and longevity of your boat.

Ageless curls the ultimate guide to curly hairstyles with bangs for women over 50

Printable physics covers a students guide to organization and creativity

Making math fun the best free online games for kindergartners

How To Wire A Bilge Pump Switch - Khao Tick On

How To Install An Automatic Bilge Pump - Khao Tick On

Bilge Pump Float Switch Wiring - Khao Tick On

Bilge Pump Wiring Diagram With Float Switch - Khao Tick On

Rule Automatic Bilge Pump Wiring Diagram - Khao Tick On

Rule Bilge Wiring Diagram - Khao Tick On

How To Replace A Bilge Pump at Brian Newberry blog - Khao Tick On

How To Wire Bilge Pump - Khao Tick On

johnson bilge pump installation - Khao Tick On

DIAGRAM 3 Way Switch Wiring Diagrams With Float Switch Bilge Pump - Khao Tick On

Bilge Pump Wiring Diagram High - Khao Tick On

Float Valve Wiring Diagram - Khao Tick On

Wiring A Automatic Bilge Pump - Khao Tick On

Wiring A Rule Bilge Pump - Khao Tick On

Rule Bilge Pump Wiring Instructions - Khao Tick On