Imagine a sunny afternoon, the gentle rocking of the boat, the wind in your hair…and then, silence. Your engine sputters and dies, leaving you stranded. A common culprit? A failing boat motor water pump. This small but mighty component is the heart of your engine's cooling system, and understanding its function is key to enjoying trouble-free boating.

A marine engine, much like a car engine, generates significant heat during operation. Without a cooling system, this heat could quickly lead to catastrophic engine failure. The boat engine water pump is responsible for circulating coolant, usually a mixture of water and antifreeze, through the engine block, absorbing this heat and preventing overheating. This coolant then passes through a heat exchanger, where the heat is dissipated, often into the surrounding water.

Early boat motors relied on simple, often unreliable, cooling methods. Direct cooling, where the engine was submerged in water, was common. However, this method was impractical for larger engines and saltwater environments. The development of the impeller-style water pump revolutionized marine engine cooling, allowing for more efficient and reliable heat management. This paved the way for the powerful and reliable boat engines we have today.

The importance of a properly functioning water pump can't be overstated. It's the silent guardian protecting your engine from overheating, which can lead to warped cylinders, cracked heads, and even complete engine seizure. A failing water pump can quickly turn a relaxing day on the water into a costly nightmare. Regular inspection and maintenance of your boat's water pump are crucial for preventing these issues.

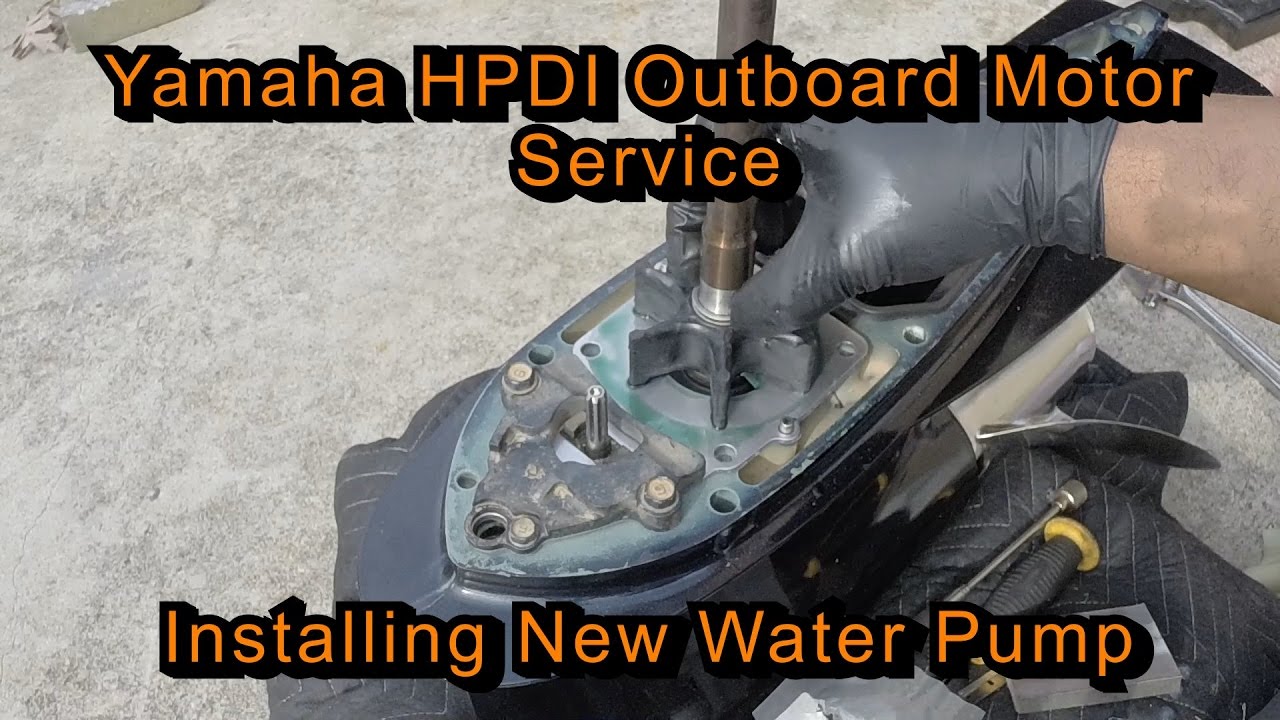

One of the most common issues boat owners face with their water pumps is impeller failure. The impeller, a rubber component within the pump, is responsible for drawing water into the system. Over time, the impeller can become brittle, cracked, or even completely disintegrate due to wear and tear, or exposure to chemicals and debris. A damaged impeller can drastically reduce the cooling system's effectiveness, leading to overheating. Regularly inspecting and replacing the impeller, typically annually, is a crucial preventive maintenance task.

Several benefits come with maintaining a well-functioning water pump. First, it prevents overheating, thus extending the lifespan of your engine. Second, it ensures optimal engine performance, allowing you to enjoy smooth and efficient operation. Finally, it provides peace of mind, allowing you to focus on enjoying your time on the water rather than worrying about potential engine problems.

One crucial aspect of boat motor water pump maintenance is regular impeller replacement. Replacing the impeller annually is a proactive measure that significantly reduces the risk of unexpected failures. Make it a part of your pre-season checklist.

Checking for leaks is another essential part of water pump maintenance. Inspect all hoses and connections regularly, looking for any signs of wear, cracks, or leaks. Address any leaks promptly to prevent further damage and ensure optimal cooling system performance.

Advantages and Disadvantages of Different Water Pump Types

While most outboard and sterndrive engines utilize impeller pumps, some larger inboard engines may use other types.

Here are some best practices for maintaining your boat's water pump:

1. Inspect the impeller annually and replace it as needed.

2. Flush the cooling system with fresh water after each use, especially in saltwater environments.

3. Check for leaks regularly and address them promptly.

4. Use a high-quality marine antifreeze in the cooling system to protect against corrosion and freezing.

5. Monitor engine temperature gauges closely while operating the boat.

Frequently Asked Questions:

1. How often should I replace my impeller? Annually, or more frequently if you use your boat often.

2. What are the signs of a failing water pump? Overheating, reduced water flow from the tell-tale, and strange noises from the pump.

3. Can I replace my impeller myself? Yes, with the right tools and a little mechanical knowledge.

4. What type of antifreeze should I use? Marine-specific antifreeze designed to protect against corrosion in saltwater environments.

5. How do I check for leaks? Visually inspect all hoses and connections for any signs of leakage.

6. What should I do if my engine overheats? Stop the engine immediately and investigate the cause.

7. How can I extend the life of my water pump? Regular maintenance and using high-quality coolants.

8. Where can I find replacement parts for my water pump? At your local marine supply store or online.

Tips and Tricks:

Keep a spare impeller onboard in case of unexpected failure. Carry a basic tool kit for performing minor repairs on the water.

In conclusion, the boat motor water pump is a critical component of your engine's cooling system, ensuring smooth operation and preventing costly damage. By understanding its function, performing regular maintenance, and addressing potential issues promptly, you can extend the life of your engine and enjoy countless hours of trouble-free boating. Don't underestimate the importance of this small but mighty device. Regular inspection, proactive maintenance, and a little knowledge can go a long way in keeping your boat's heart beating strong and ensuring your adventures on the water are smooth sailing. Remember, a well-maintained boat is a happy boat! Invest the time and effort to care for your water pump, and it will reward you with reliable performance and peace of mind on the water. Now, get out there and enjoy the open water!

Unlocking the potential of builders beige paint

Romes upcoming weather a comprehensive guide

Elevating exteriors behr premium plus ultra paint

Yamaha 250 Sho Parts Diagram - Khao Tick On

Home Products 3 Gm RV Supreme 12V Water Pump - Khao Tick On

Infiniti FX35 Engine Water Pump Main Engine Water Pump - Khao Tick On

Subaru Forester Engine Water Pump Gasket Engine Water Pump - Khao Tick On

Infiniti FX35 Engine Water Pump Main Engine Water Pump - Khao Tick On

Float Switch Wiring Diagram for Single Phase Water Pump - Khao Tick On

water pump for boat motor - Khao Tick On

6 Blade Water Pump Impeller 382221 Marine Impeller for Johnson Evinrude - Khao Tick On

Jet Ski Engine And Pump - Khao Tick On

Mercury Outboard Parts Diagram Models - Khao Tick On

Buy Water Pump Boat at Marsha Burroughs blog - Khao Tick On

Gamefisher 5 Hp Outboard Parts - Khao Tick On

NO17 Submersible Water Pump 35W 2500 LH Aquarium Pump Ultra - Khao Tick On

Pump Sauce contemplates a Muscle Mommy Bath Water flavor - Khao Tick On

Barrelled Water Automatic Pumper Water Pump - Khao Tick On