Ever wonder what keeps that roaring beast of a lawnmower chugging along? Sure, you know there's gas involved, but there's a tiny, unsung hero working tirelessly behind the scenes: the small engine fuel pump. This little gizmo is the lifeblood of your outdoor power equipment, and understanding its function can save you from a world of frustration (and expensive repairs).

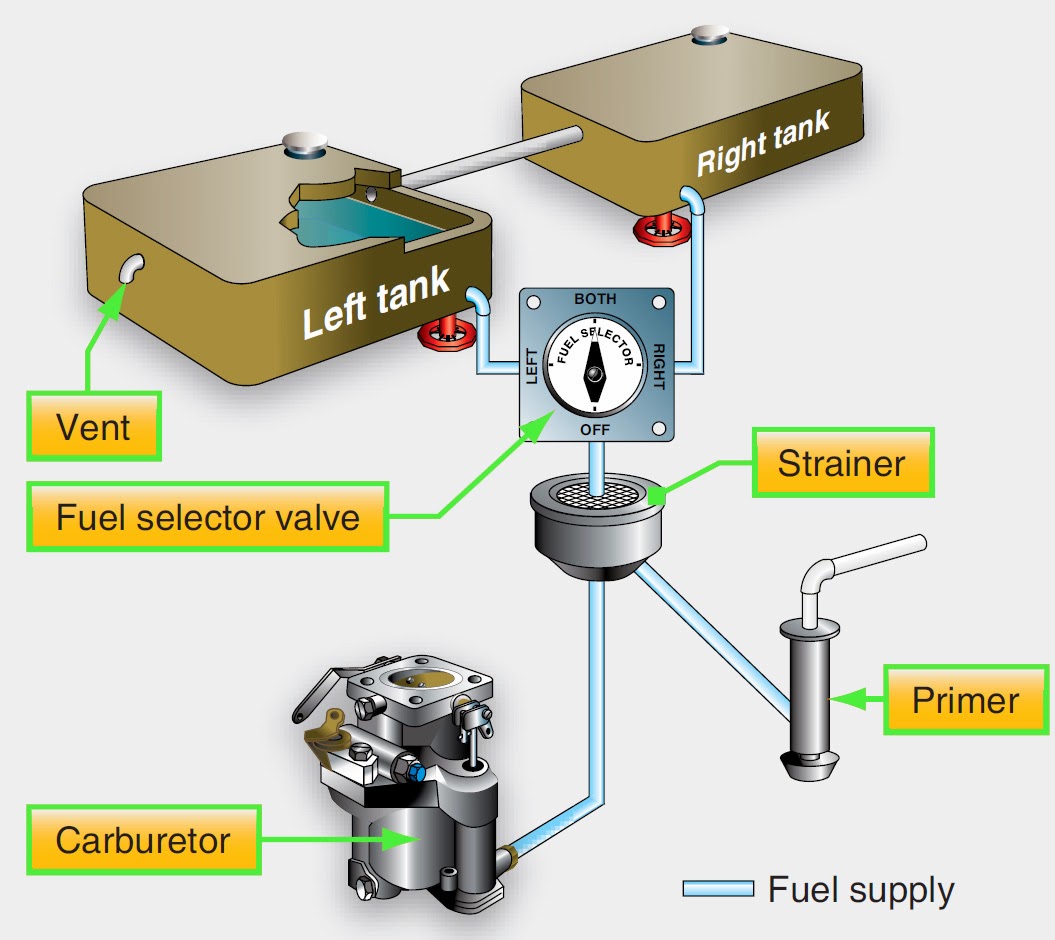

So, what exactly is this magical fuel-pumping marvel? In essence, it's a compact pump designed to deliver a steady stream of fuel from the tank to the carburetor. This consistent flow ensures your engine gets the juice it needs to purr (or roar, depending on your equipment) like a well-oiled machine. Without it, your lawnmower might sputter, stall, or refuse to start altogether. Think of it as the heart of your small engine's circulatory system.

Small engine fuel pumps have been around for decades, evolving from simple mechanical diaphragms to more complex vacuum and pulse-operated designs. The core principle remains the same: to get fuel from point A to point B efficiently. This seemingly simple task is crucial for the smooth operation of everything from lawnmowers and chainsaws to leaf blowers and generators. The history of these pumps is intricately linked to the development of small gasoline engines themselves, as the need for a reliable fuel delivery system became increasingly important.

The importance of proper small engine fuel pump operation cannot be overstated. A malfunctioning pump can lead to a host of issues, from poor engine performance and increased fuel consumption to difficulty starting and even complete engine failure. Understanding how these pumps work and how to troubleshoot common problems can save you time, money, and a whole lot of headaches.

Several factors can contribute to fuel pump problems. Clogged fuel lines, a ruptured diaphragm, or a faulty check valve can all disrupt the flow of fuel and cause performance issues. Regular maintenance, including cleaning the fuel system and replacing the fuel filter, can help prevent these problems and extend the life of your small engine.

Fuel pump operation is fairly straightforward. Most small engines use a pulse-type fuel pump, which utilizes pressure pulses created by the engine's crankcase to operate the pump diaphragm. This diaphragm creates a vacuum that draws fuel from the tank and pushes it towards the carburetor. A check valve prevents fuel from flowing back into the tank, ensuring a constant supply to the engine.

Benefits of a properly functioning fuel pump include: 1) Reliable starting, 2) Consistent engine performance, 3) Optimal fuel efficiency.

Troubleshooting tips: If your engine is experiencing fuel delivery issues, start by checking the fuel lines for kinks or blockages. Inspect the fuel filter and replace it if necessary. If these checks don't reveal the problem, the fuel pump itself may be faulty and require replacement.

Advantages and Disadvantages of Mechanical Fuel Pumps

| Advantages | Disadvantages |

|---|---|

| Simplicity | Can be less reliable than electric pumps |

| Lower cost | Susceptible to vapor lock |

Best Practices: 1) Use fresh, clean fuel. 2) Regularly replace the fuel filter. 3) Inspect fuel lines for leaks or damage. 4) Store your equipment properly during the off-season. 5) Consult a qualified technician for any complex repairs.

FAQ: 1) How do I know if my fuel pump is bad? 2) How much does a replacement fuel pump cost? 3) Can I replace the fuel pump myself? 4) What type of fuel should I use in my small engine? 5) How often should I replace the fuel filter? 6) How do I clean my fuel system? 7) What is a fuel pump diaphragm? 8) How does a pulse-type fuel pump work?

Tips and tricks: Adding a fuel stabilizer can help prevent fuel degradation during storage. Regularly draining the fuel tank can also help prevent issues caused by stale fuel.

In conclusion, the small engine fuel pump may be small in size, but its role in the operation of your outdoor power equipment is enormous. Understanding how it functions, performing regular maintenance, and knowing how to troubleshoot common problems can ensure your engine runs smoothly and reliably for years to come. From lawnmowers to chainsaws, this little component keeps our yards manicured and our trees trimmed. So next time you fire up your trusty lawnmower, take a moment to appreciate the unsung hero that is the small engine fuel pump – it's the tiny powerhouse that keeps our outdoor world running. By taking the time to learn about small engine fuel pump maintenance and repair, you can save money and extend the lifespan of your valuable equipment. Don't let a faulty fuel pump bring your outdoor projects to a screeching halt – take control of your small engine's health and keep it running strong.

Unlocking the potential of sherwin williams connected gray 6165

Beyond the beaches uncovering the mejores restaurantes en puerto rico

Ancient cache of technologies dark energy

Small Engine Fuel Pump Diagram - Khao Tick On

Checking a mechanical fuel pump - Khao Tick On

Small Engine Fuel Pump - Khao Tick On

Wiring Electric Fuel Pump On Carbureted Motor - Khao Tick On

Fuel Pump Electrical Diagram - Khao Tick On

Small Engine Electric Fuel Pump 12v - Khao Tick On

Diagram Of A Car Fuel System - Khao Tick On

small engine fuel pump operation - Khao Tick On

Fuel Line For Small Engine at Augustine Mendoza blog - Khao Tick On

Fuel Pump Engine Light - Khao Tick On

Small Engine Vacuum Fuel Pump at Michael Douglas blog - Khao Tick On

Fuel Tank Inerting System A320 - Khao Tick On

Aircraft Fuel System Design - Khao Tick On

Honda small engine pulse fuel pump - Khao Tick On

Small Engine Fuel Pump Diagram - Khao Tick On