Ever found yourself staring blankly at a toolbox full of sockets, unsure which one to grab? You're not alone. The world of tools can be a confusing place, especially when it comes to the age-old debate: metric versus SAE sockets. While it might seem like a minor detail, using the wrong type of socket can lead to stripped bolts, damaged tools, and a whole lot of frustration.

At its core, the difference between metric and SAE (Society of Automotive Engineers) sockets boils down to their measurement systems. Metric sockets, as their name suggests, adhere to the metric system, using millimeters as their primary unit of measurement. SAE sockets, on the other hand, are based on inches, a remnant of their American automotive industry origins.

This fundamental difference in measurement is reflected in the sockets' physical dimensions. Metric sockets are typically sized in increments of millimeters, such as 10mm, 12mm, or 14mm. SAE sockets, however, utilize fractional inch measurements, like 3/8 inch, 1/2 inch, or 9/16 inch.

The historical roots of this measurement discrepancy can be traced back to the early 20th century. As the automotive industry boomed, manufacturers on either side of the Atlantic adopted their own standards. American carmakers embraced the familiar inch-based SAE system, while their European counterparts gravitated towards the metric system. This division has persisted over the decades, leading to the two distinct socket systems we use today.

So why does this difference matter? Imagine trying to force a square peg into a round hole – that's essentially what happens when you use the wrong type of socket. A metric socket will not properly fit onto an SAE bolt, and vice versa. Attempting to do so can damage the bolt head, making it incredibly difficult (if not impossible) to remove. Moreover, using the wrong socket can also lead to the tool slipping, potentially causing injury.

Advantages and Disadvantages of Metric and SAE Sockets

While there's no inherent advantage to one system over the other, understanding their differences is key to selecting the right tool for the job.

| Feature | Metric Sockets | SAE Sockets |

|---|---|---|

| Measurement System | Metric (millimeters) | Imperial (inches) |

| Common Sizes | 10mm, 12mm, 14mm | 3/8", 1/2", 9/16" |

| Typical Applications | Vehicles manufactured outside the US, electronics, bicycles | Vehicles manufactured in the US (pre-1980s), machinery, plumbing |

Best Practices for Working with Metric and SAE Sockets

To avoid any mishaps and ensure you're using the right socket every time, keep these best practices in mind:

- Identify the fastener: Before reaching for a socket, carefully examine the bolt or nut you're working with. Look for markings indicating its size and measurement system. Metric fasteners often have numbered markings, while SAE fasteners may have lines or dashes indicating size.

- Invest in a socket set: Having a comprehensive set of both metric and SAE sockets is crucial, especially if you work on a variety of projects. This ensures you'll have the right tool for the job, regardless of the fastener type.

- Organize your sockets: Keep your sockets organized to save time and prevent confusion. Socket organizers or trays can help you quickly locate the correct size and type of socket.

- Start with a snug fit: When attaching a socket to a fastener, ensure a snug fit before applying any torque. If the socket feels loose or wobbly, you're likely using the wrong type.

- Don't force it: Never force a socket onto a fastener. If it doesn't fit easily, double-check your measurements and try a different socket.

Common Questions about Metric and SAE Sockets

Let's address some frequently asked questions about metric and SAE sockets:

- Q: Can I use a metric socket on an SAE bolt, or vice versa?

A: No, it's crucial to use the correct socket type that matches the fastener. Using the wrong one can damage the bolt or the tool. - Q: How can I tell if a bolt is metric or SAE?

A: Look for markings on the bolt head. Metric bolts often have numbered sizes, while SAE bolts may have lines indicating size. - Q: What happens if I use the wrong size socket?

A: Using the wrong size can round off the bolt head, making it extremely difficult to remove. It's essential to use the correct size socket for a secure and damage-free grip.

Understanding the difference between metric and SAE sockets is an essential part of being a handy individual. By knowing the key distinctions, investing in the right tools, and following best practices, you'll be well-equipped to tackle any project with confidence, ensuring that your wrenching endeavors are met with success rather than frustration. So, the next time you're facing a stubborn bolt, you'll know exactly which socket to grab. Happy wrenching!

Unlocking reactions the power of potential energy diagrams

Stain escape artists moreton wirral dry cleaning deep dive

Navigating medicare unpacking blue cross plan g plus

Metric Conversion Chart For Grade 7 - Khao Tick On

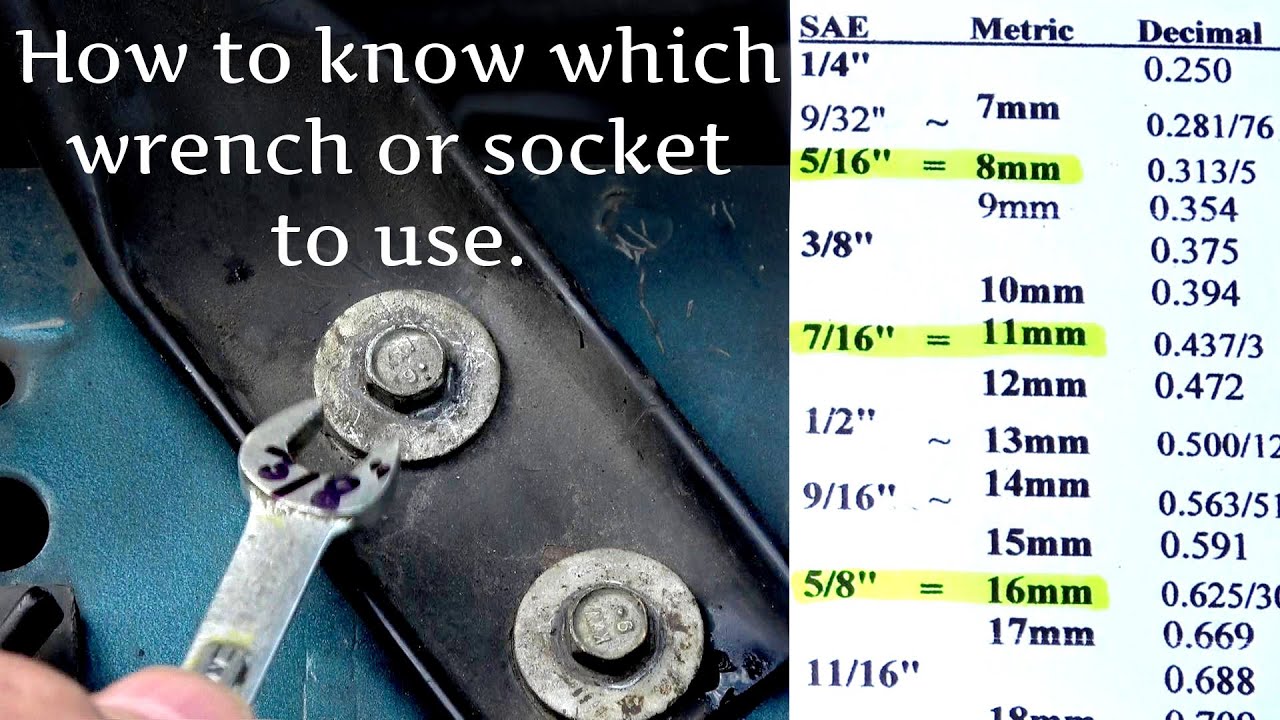

Wrench Conversion Chart for SAE & Metric Sizes w/ Bolt Diameter Guide - Khao Tick On

Wrench Size Chart Pdf - Khao Tick On

Printable Socket Size Chart - Khao Tick On

Sae Metric Conversion Chart - Khao Tick On

Sae Size Chart Sockets - Khao Tick On

Metric To Standard Conversion Chart Wrenches - Khao Tick On

Sae To Metric Thread Conversion Chart - Khao Tick On

Choose actual DWP calculation have must pays - Khao Tick On

Standard Socket Wrench Size Chart - Khao Tick On

Printable Standard Wrench Size Chart - Khao Tick On

SAE METRIC WRENCH INTERCHANGE MAGNETIC CHART TOOL BOX SHOP GARAGE - Khao Tick On

Wrench Size Chart Metric - Khao Tick On

Printable Wrench Size Chart - Khao Tick On

Socket Wrench Conversion Chart - Khao Tick On