Is your HVAC system struggling to keep up? Are some rooms too hot while others are too cold? The culprit might be inefficient airflow within your ductwork. Understanding and utilizing a flexible duct airflow diagram can be the key to unlocking optimal comfort and energy efficiency in your home or office. This guide will delve into the world of flex duct air flow diagrams, providing you with the knowledge to maximize your HVAC system's performance.

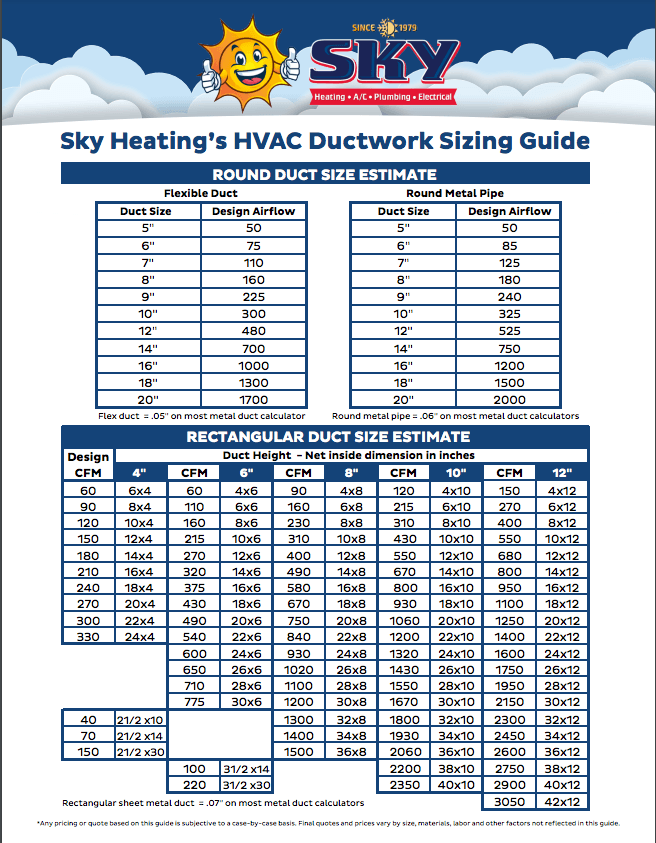

A flex duct airflow diagram, also referred to as a flex duct pressure drop chart or a flexible ductwork airflow calculator guide, is a crucial tool for HVAC professionals and DIY enthusiasts alike. This visual representation depicts the relationship between airflow rate, duct diameter, and static pressure loss in flexible ductwork. By understanding this relationship, you can accurately size your ducts and ensure proper airflow throughout your space. This can translate to lower energy bills, improved indoor air quality, and a more comfortable environment.

While pinpointing the precise origin of flex duct airflow charts is difficult, their development is closely tied to the rise of flexible ductwork itself in the mid-20th century. As flexible ducts became a popular alternative to rigid metal ducts, the need to understand their unique airflow characteristics became apparent. Early charts were likely based on experimental data and gradually refined over time with advancements in fluid dynamics and computer modeling. The importance of these charts cannot be overstated. They provide a standardized way to analyze and design flexible duct systems, ensuring efficient and balanced airflow.

One of the main issues surrounding flex duct airflow diagrams is their potential for misinterpretation. Unlike rigid ducts, the flexibility of flex duct can lead to variations in cross-sectional area, impacting airflow. Compressed or kinked sections can significantly restrict airflow, leading to reduced system efficiency and increased energy consumption. Properly understanding how to read and apply the information within these diagrams, coupled with correct installation techniques, is essential to avoid these pitfalls.

A simplified example: Imagine two flex ducts of the same length, but one is significantly compressed. According to a flex duct airflow chart, both should deliver the same airflow at a given pressure. However, the compressed duct will experience a much higher pressure drop, reducing the actual airflow and straining the HVAC system. This illustrates the importance of maintaining proper duct shape and minimizing restrictions.

One benefit of using a flex duct air flow chart is achieving optimal system efficiency. By correctly sizing ducts and minimizing pressure drops, you can reduce the load on your HVAC equipment, leading to lower energy consumption and cost savings. Another advantage is improved indoor air quality. Balanced airflow ensures proper ventilation and prevents stagnant air pockets, which can harbor dust, allergens, and other pollutants. Finally, accurate airflow design leads to enhanced comfort. By distributing air evenly throughout your space, you can eliminate hot and cold spots, creating a more consistent and comfortable environment.

Advantages and Disadvantages of Using Flex Duct Air Flow Charts

| Advantages | Disadvantages |

|---|---|

| Accurate duct sizing | Potential for misinterpretation |

| Improved system efficiency | Requires understanding of HVAC principles |

| Enhanced indoor air quality | Doesn't account for installation errors |

Best Practice 1: Always consult the manufacturer's specifications for the specific type of flex duct you are using, as airflow characteristics can vary between brands and models.

Best Practice 2: Ensure the flex duct is fully extended and not compressed or kinked during installation. This will maintain the intended cross-sectional area and minimize pressure drop.

Best Practice 3: Use smooth bends and avoid sharp turns whenever possible. Sharp bends can disrupt airflow and increase pressure drop.

Best Practice 4: Insulate your flex duct to minimize heat transfer and improve energy efficiency. This is especially important in unconditioned spaces like attics and crawlspaces.

Best Practice 5: Regularly inspect your ductwork for leaks, kinks, or other damage. Addressing these issues promptly can prevent airflow problems and maintain system efficiency.

FAQ 1: What is a flex duct airflow chart? Answer: It's a visual guide showing the relationship between airflow, duct diameter, and pressure drop.

FAQ 2: Why is it important to use a flex duct airflow chart? Answer: To ensure proper duct sizing and efficient airflow.

Tips and tricks: When working with a flex duct airflow calculator, consider using online resources to automate calculations and ensure accuracy.

In conclusion, understanding and utilizing a flex duct air flow chart is crucial for achieving optimal HVAC system performance. While potential challenges exist, the benefits of proper airflow design are undeniable. From reduced energy bills and improved indoor air quality to enhanced comfort, a well-designed flex duct system can significantly improve your living or working environment. By following best practices, consulting manufacturer specifications, and staying informed about the latest advancements in flexible duct technology, you can ensure your HVAC system operates at peak efficiency, providing years of reliable and comfortable service. Take the time to learn about flex duct airflow principles and empower yourself to create a more comfortable and efficient space. Don't hesitate to consult with HVAC professionals for complex projects or if you have any doubts about your system's design.

Taming unruly excel cells making text fit perfectly

Hwy 41 southbound crash impacts traffic today

Decoding the hvac fan relay switch your key to climate control

Cfm Chart Flex Duct - Khao Tick On

Exhaust Duct Sizing at Muriel Jacobs blog - Khao Tick On

Air Conditioner Vent Parts at Wendy Thompson blog - Khao Tick On

Air Hose Size Chart - Khao Tick On

Duct Design Handbook at Kevin Reed blog - Khao Tick On

Exhaust Duct Sizing at Muriel Jacobs blog - Khao Tick On

Flex Duct Sizing Chart - Khao Tick On

Home Air Ventilation Stunning Hvac Duct Sizes Duct Sizing Chart - Khao Tick On

Requirements for HVAC Return Air with a Duct Sizing Chart - Khao Tick On

Flex Duct Sizing Chart - Khao Tick On

How To Use A Duct Calculator at Luis King blog - Khao Tick On

Calculating Duct Size For Cfm - Khao Tick On

Flex Duct Sizing Chart - Khao Tick On

Kea General Information Sizing within Flex Duct Sizing Chart 24391 - Khao Tick On

Flex Duct Flow Chart - Khao Tick On