Ever found yourself staring at a wheel stud, wondering about its dimensions? You’re not alone. Knowing how to determine the size of a wheel stud is a surprisingly useful skill, whether you're a seasoned mechanic or just a car owner dealing with a flat tire. Getting the right measurement ensures a safe and secure wheel fitment, preventing potential hazards down the road. So, let's dive into the world of wheel stud measurement.

Accurate wheel stud measurement is crucial for proper wheel installation. An incorrect measurement can lead to loose wheels, vibrations, and even wheel detachment, creating dangerous driving conditions. Understanding the dimensions of your wheel studs is a fundamental aspect of car maintenance and safety.

The history of wheel studs parallels the evolution of the automobile itself. Early vehicles utilized simpler fastening methods, but as cars became faster and more complex, the need for secure wheel attachments became paramount. Wheel studs emerged as a robust solution, and their dimensions have been standardized over time to ensure compatibility and safety.

Measuring a wheel stud involves determining two key parameters: the diameter and the length. The diameter, or thickness, of the stud is critical for matching the correct lug nuts. The length determines how securely the wheel can be attached. Both measurements are essential for a proper fit.

While the concept might seem straightforward, there are common pitfalls to avoid. Using the wrong measuring tool, misreading the measurement, or failing to account for thread pitch can lead to inaccurate results. This underscores the importance of understanding the correct techniques and having the right tools at hand.

One significant benefit of knowing how to measure wheel studs is the ability to purchase the correct replacement studs. If a stud is damaged or sheared, having accurate measurements ensures a seamless replacement process. For example, if you measure a stud diameter of 12mm and a length of 25mm, you can confidently order the correct replacement part.

Another advantage is the ability to select appropriate aftermarket wheels. Different wheels require specific stud lengths and diameters. Knowing your stud dimensions allows you to choose wheels that are compatible with your vehicle, avoiding fitment issues and potential safety risks.

Furthermore, accurate stud measurement is essential for diagnosing wheel-related problems. If you experience wheel wobble or vibration, knowing your stud dimensions can help determine if the issue stems from incorrect stud length or a damaged stud. This can save you time and money on unnecessary repairs.

To measure the diameter, you'll need a caliper or a micrometer. Place the caliper jaws around the stud shaft and tighten until snug. The reading on the caliper will indicate the diameter. For the length, measure from the base of the stud where it meets the hub to the tip of the stud.

A quick checklist: 1. Clean the stud. 2. Use a calibrated caliper or micrometer. 3. Measure the diameter. 4. Measure the length. 5. Record your measurements.

Step-by-step guide: 1. Clean the wheel stud to remove any dirt or debris. 2. Using a caliper, measure the diameter of the stud shaft. 3. Using a ruler or caliper, measure the length of the stud from its base to the tip. 4. Double-check your measurements for accuracy.

Advantages and Disadvantages of Accurate Wheel Stud Measurement

| Advantages | Disadvantages |

|---|---|

| Ensures proper wheel fitment | Requires specific tools like calipers |

| Prevents wheel-related issues | Can be time-consuming if rust or debris is present |

Best Practices: 1. Always use a clean caliper. 2. Measure twice to ensure accuracy. 3. Consider thread pitch. 4. Consult your vehicle's manual for specifications. 5. If unsure, consult a professional.

Real Examples: 1. Replacing a broken stud on a Honda Civic. 2. Installing aftermarket wheels on a Jeep Wrangler. 3. Diagnosing wheel wobble on a Toyota Camry.

Frequently Asked Questions: 1. What tools do I need? 2. How often should I check my studs? 3. What if my stud is damaged?

Tips and Tricks: Use a thread pitch gauge to determine the thread size. Clean the threads with a wire brush for accurate measurements.

In conclusion, understanding how to ascertain the dimensions of your wheel studs is a fundamental skill for any car owner. Accurate measurement ensures proper wheel installation, prevents potential safety hazards, and empowers you to make informed decisions about maintenance and repairs. By following the steps outlined in this guide, you can confidently measure your wheel studs and contribute to the safety and longevity of your vehicle. Investing a little time in learning this process can save you from significant headaches down the road, ensuring a smooth and safe driving experience. Don't underestimate the importance of this seemingly small detail; it plays a vital role in the overall performance and safety of your vehicle. Take the time to learn, practice, and prioritize the correct measurement of your wheel studs.

Pre owned rav4 hybrid limited unleash your inner eco warrior

Unlock your roblox identity the ultimate guide to usernames

Navigating employee protection your guide to borang daftar pekerja perkeso

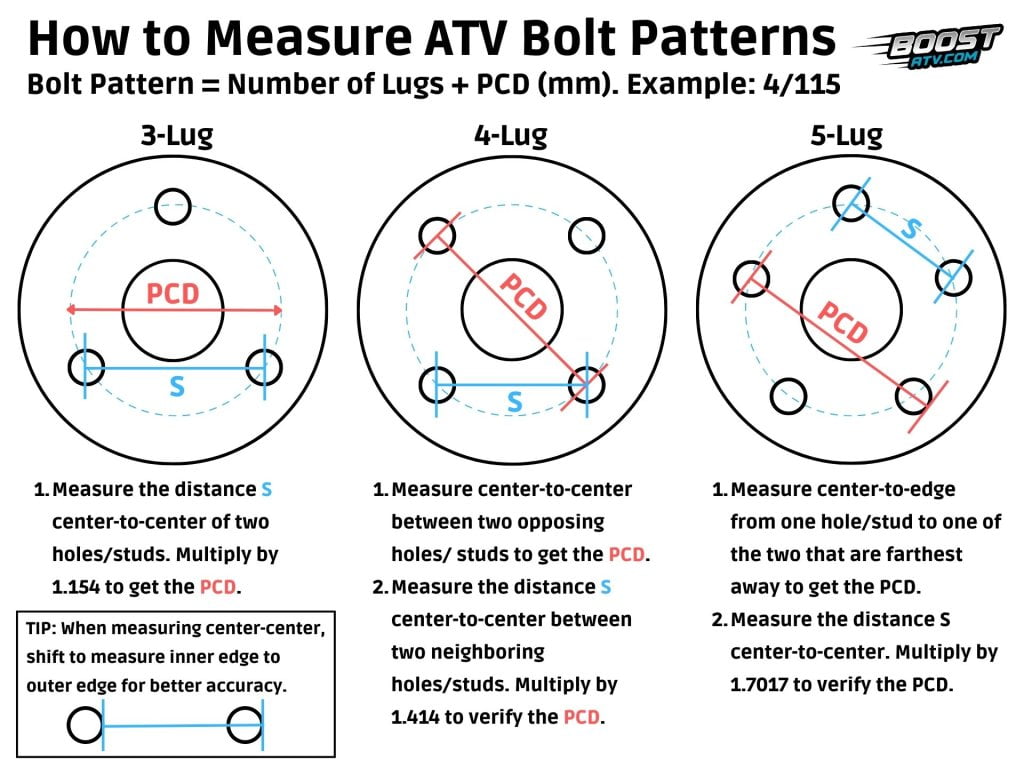

ATV Wheel Bolt Pattern and Lug Pattern Explained - Khao Tick On

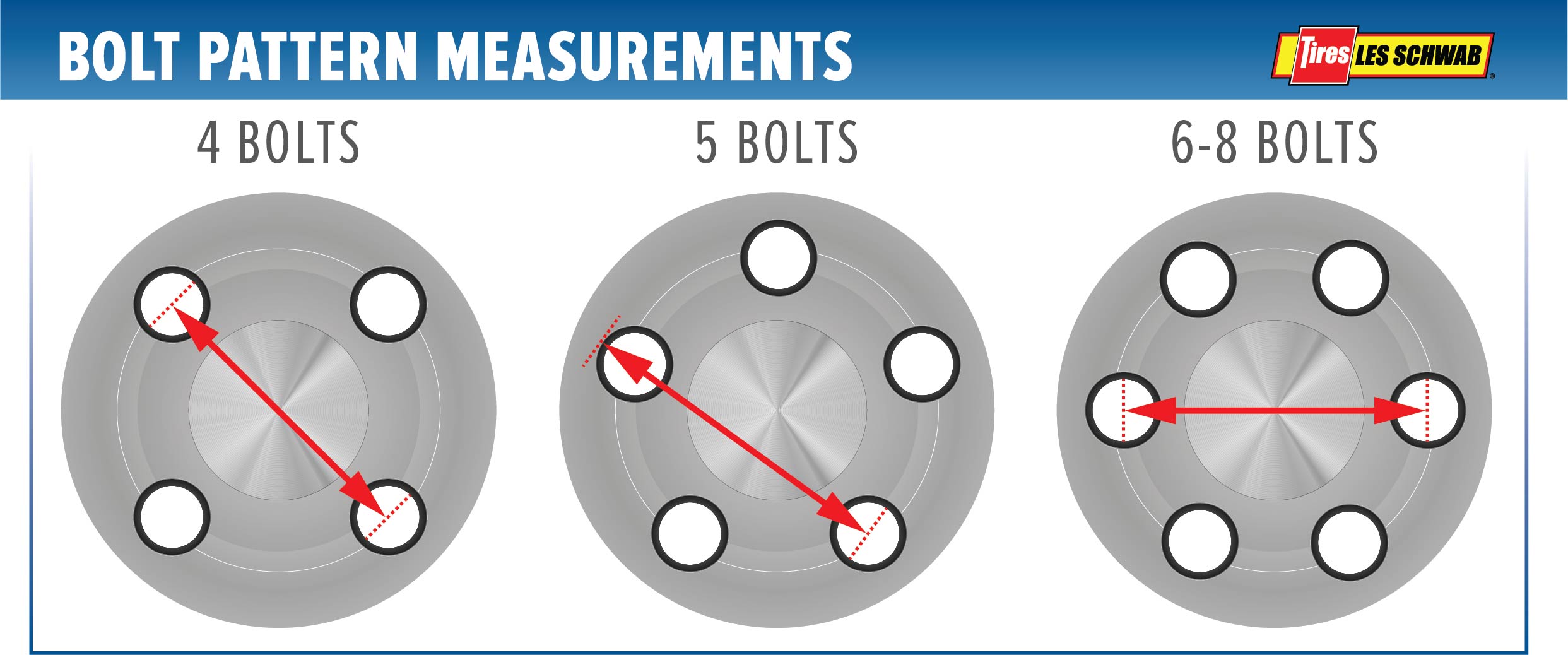

How To Measure Wheel Stud Pattern - Khao Tick On

Bmw Wheel Bolt Pattern Guide - Khao Tick On

2018 Ford F 150 Bolt Pattern - Khao Tick On

How To Measure Wheel Lug Spacing 5x45 - Khao Tick On

How To Measure A Rim Lug Pattern at Carmen Reed blog - Khao Tick On

How Do You Measure Wheel Lug Pattern at Mattie Smith blog - Khao Tick On

How To Measure Chevy Wheel Bolt Pattern at Norman Donato blog - Khao Tick On

Bmw Bolt Pattern Size - Khao Tick On

Chevy Wheel Bolt Pattern Chart - Khao Tick On

2001 Chevy Silverado 1500 Bolt Pattern - Khao Tick On

Chevy Malibu Wheel Bolt Pattern - Khao Tick On

how to measure a wheel stud - Khao Tick On

Dodge 6 Lug Bolt Pattern - Khao Tick On

Trailer Lug Pattern Chart - Khao Tick On