Ever had a power tool act up on you mid-project? A sudden spark, a weird smell, or maybe even a small shock? It's a jarring experience, and it's a stark reminder of the potential dangers lurking within our workshops and toolboxes. This is why regular portable electrical tool inspection is so crucial – it's about more than just keeping your tools working; it's about keeping you safe.

Portable power tools are the backbone of countless projects, from DIY home repairs to professional construction. We rely on their power and convenience to get things done, but that reliance comes with a responsibility. These tools, by their very nature, present electrical hazards. Damage to cords, plugs, or internal wiring can create risks of shocks, burns, and even fires. A thorough examination of portable electrical tools can identify these issues before they turn into dangerous situations.

The practice of inspecting electrical equipment has its roots in the industrial revolution, as electricity became a widespread power source. Early electrical systems were often unreliable and prone to failure, highlighting the need for regular checks. Over time, as tools became more portable and accessible, the focus shifted towards ensuring the safety of individual users. Regulations and standards emerged, solidifying the importance of portable electrical tool inspection in preventing workplace accidents and maintaining equipment integrity.

One of the major challenges in maintaining portable electrical tool safety is the inherent wear and tear these tools experience. They're often subjected to harsh conditions – dropped, dragged, exposed to moisture and dust. This constant exposure increases the likelihood of damage, making regular assessments even more critical. Another key issue is user behavior. Improper usage, such as overloading circuits or using tools in wet conditions, can significantly accelerate wear and tear, amplifying the importance of user education and training.

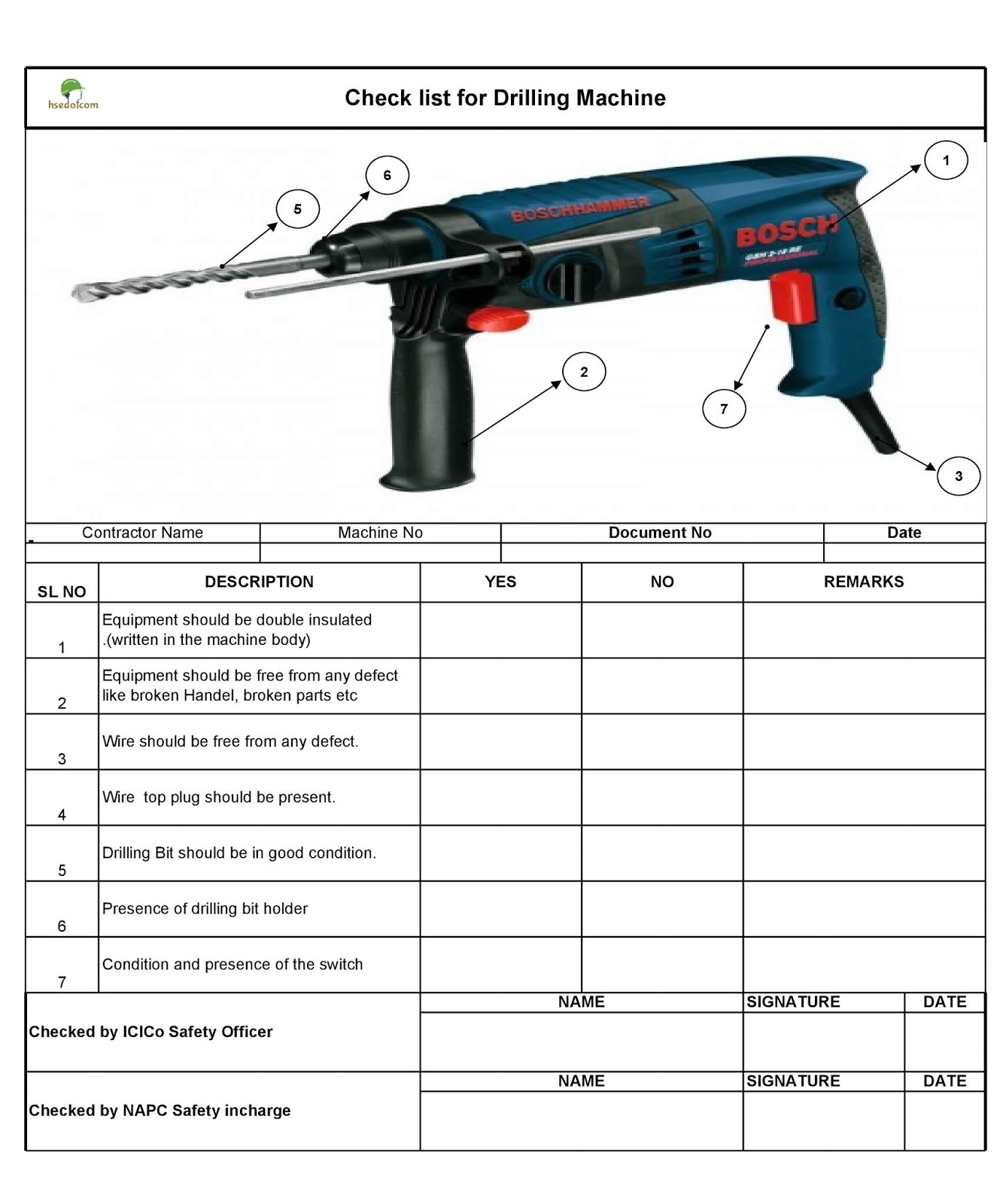

A portable electrical tool inspection involves a systematic evaluation of the tool's condition, looking for any signs of damage or wear that could pose a safety hazard. This includes checking the power cord for fraying or cuts, inspecting the plug for bent prongs or loose connections, and examining the tool's housing for cracks or damage. It also involves testing the tool's operation to ensure it's functioning correctly and doesn't overheat.

Benefit 1: Enhanced Safety - Regular checks dramatically reduce the risk of electrical shocks, burns, and fires, safeguarding both users and the surrounding environment. For example, identifying a frayed cord before it exposes live wires prevents a potential shock hazard.

Benefit 2: Extended Tool Lifespan - Catching minor issues early on can prevent them from developing into major problems, extending the lifespan of your tools. A simple tightening of loose screws can prevent further damage and costly repairs.

Benefit 3: Improved Productivity - Downtime caused by faulty tools can disrupt workflows. Regular inspections keep your tools in optimal working condition, minimizing interruptions and maximizing productivity.

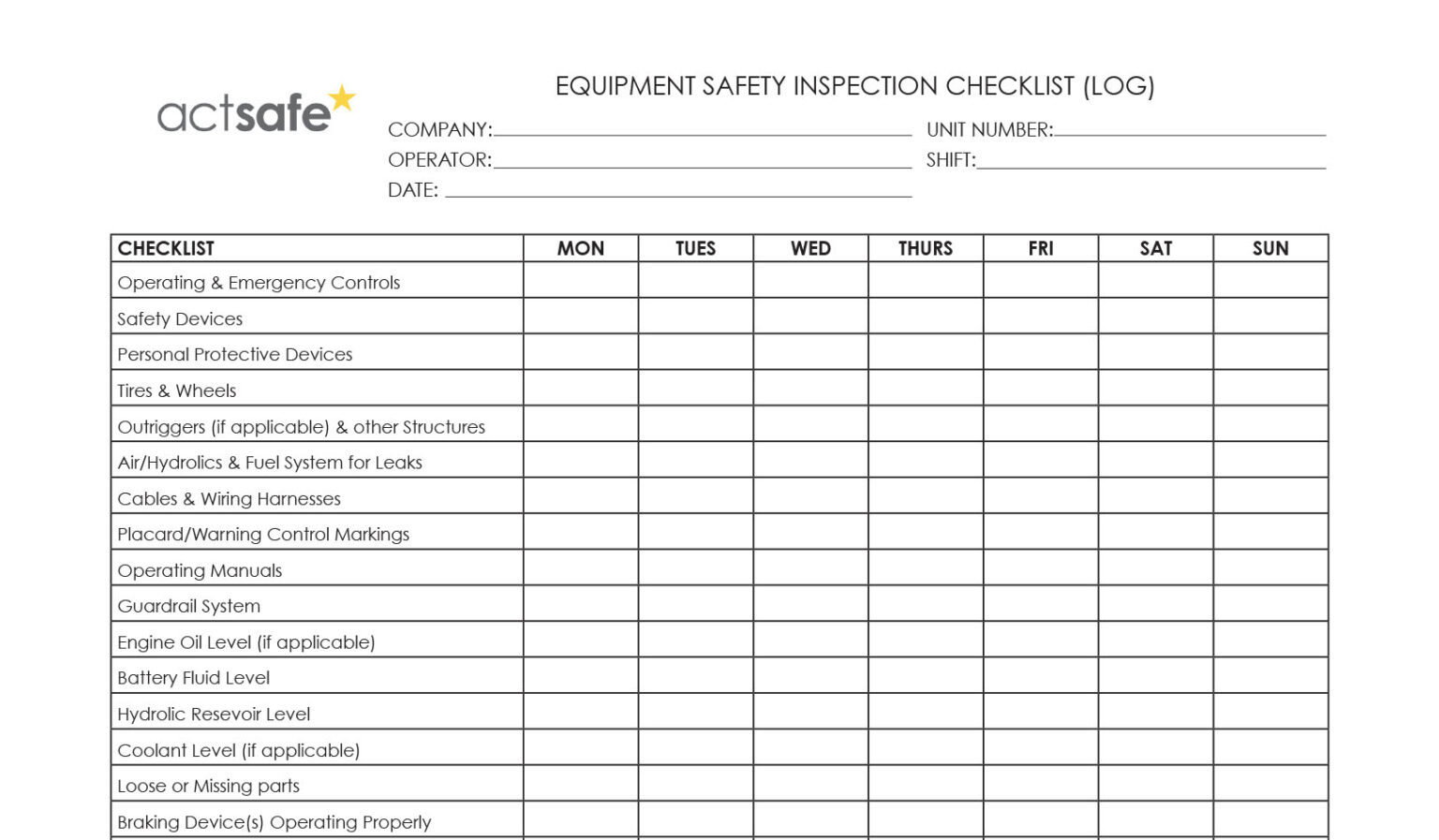

Action Plan: Create a schedule for inspections – weekly for heavily used tools, monthly for others. Keep a logbook of inspection dates and any repairs performed. Train all users on proper tool usage and inspection procedures.

Checklist: Power cord condition, plug integrity, housing for damage, switch operation, proper grounding, temperature during operation, any unusual noises or vibrations.

Step-by-Step Guide: 1. Unplug the tool. 2. Visually inspect the cord, plug, and housing. 3. Test the switch and other controls. 4. Run the tool briefly to check for overheating or unusual noises. 5. Log the inspection date and any findings.

Advantages and Disadvantages of Portable Electrical Tool Inspection

| Advantages | Disadvantages |

|---|---|

| Increased safety | Requires time and resources |

| Prolonged tool life | Can disrupt workflow if issues are found |

| Reduced downtime | Requires training and knowledge |

Best Practices: 1. Always unplug before inspecting. 2. Use a checklist. 3. Document findings. 4. Train all users. 5. Establish a regular inspection schedule.

Real Examples: 1. A frayed cord discovered during an inspection prevents a potential shock incident. 2. A loose connection identified prevents a tool malfunction. 3. Regular maintenance extends the life of a drill by several years. 4. Inspection reveals a damaged switch, preventing potential overheating. 5. A cracked housing is replaced, avoiding potential exposure to internal wiring.

Challenges and Solutions: 1. Lack of time – Schedule dedicated time for inspections. 2. Lack of training – Provide comprehensive training to all users. 3. Resistance to change – Emphasize the safety and cost-saving benefits. 4. Difficulty tracking inspections – Implement a digital logbook system. 5. Cost of repairs – Factor repair costs into the budget.

FAQs: 1. How often should I inspect my tools? - Depends on usage, but at least monthly. 2. Who should perform the inspections? - Trained personnel. 3. What should I look for during an inspection? - Damage to cords, plugs, and housing. 4. What should I do if I find a problem? - Remove the tool from service and repair it. 5. What are the consequences of not inspecting tools? - Increased risk of accidents and tool failure. 6. Are there any regulations regarding tool inspection? - Yes, OSHA and other agencies have regulations. 7. Where can I find more information on tool safety? - OSHA website, manufacturer manuals. 8. What are the best practices for tool storage? - Dry, secure location.

Tips and Tricks: Use brightly colored tape to mark inspection dates on tools. Keep a dedicated tool inspection kit with essential tools and supplies. Take photos of any damage found for documentation purposes. Create a designated area for tool inspection to minimize distractions.

In conclusion, portable electrical tool inspection isn't just a good idea; it's essential for maintaining a safe and productive work environment. By implementing a regular inspection program, training users, and addressing potential hazards proactively, you significantly reduce the risk of accidents and extend the lifespan of your valuable tools. Remember, a few minutes spent on inspection can save you from significant downtime, costly repairs, and most importantly, prevent injuries. Make portable electrical tool safety a top priority, and cultivate a culture of proactive maintenance to reap the long-term benefits of a well-maintained and safe tool inventory. This commitment not only protects your investment in tools but also safeguards the well-being of everyone who uses them. Start today by implementing a regular inspection schedule and ensure that all users are properly trained. Your safety, and the longevity of your tools, depend on it.

Unlocking the secrets of the ea fc live editor

Unraveling the allure of nero wolfe mystery episodes

Nero bot discord silence troubleshooting unresponsive bots

Portable Ladder Inspection Checklist - Khao Tick On

Electrical Material List Example at Yvonne Strong blog - Khao Tick On

Free Electrical Inspection Report Template Word - Khao Tick On

Machine and Equipments Weekly Inspection Check List in excel Format - Khao Tick On

Electrical panel inspection checklist pdf Fill out sign online - Khao Tick On

Electrical Tool Inspection Checklist Free To Use And 49 OFF - Khao Tick On

Checklist For Electrical Inspection - Khao Tick On

Ladder Safety Check Sheet - Khao Tick On

portable electrical tools inspection - Khao Tick On

Hand Power Tools Inspection Checklist at Cheryl Garnes blog - Khao Tick On

Portable Hand Tools Log - Khao Tick On

how to do a home electrical inspection - Khao Tick On

Equipment Safety Inspection Log - Khao Tick On

Equipment Safety Inspection Log - Khao Tick On

Visual Inspection Of Electrical Appliances at Frances Gibson blog - Khao Tick On